Our biggest USP lies in providing consistent quality delivered at the right price ..

Our biggest USP lies in providing consistent quality delivered at the right price ..

In an interviwe to infastructure line

Jayanta Ray explains the importance of selecting the right hydraulic fluid to protect the equipment in challenging conditions.

the needs of lubricant marketers to meet more regulatry standerds and challenging spacification is growing

which user segments are the biggest demand drivers for your product, and demands made by end users

Global perspective and trends in the lubricants industry

Energy has been mankind's constant companion and will continue to be crucial in the future.

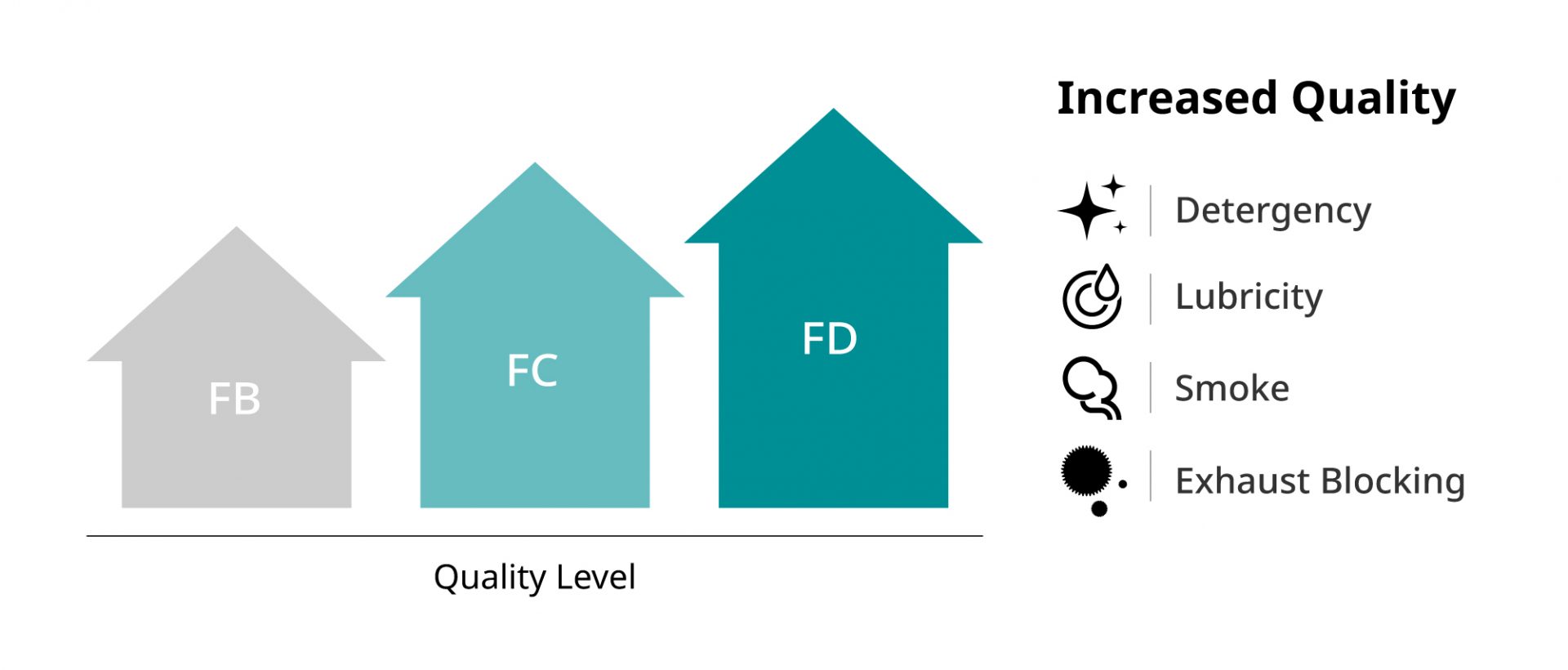

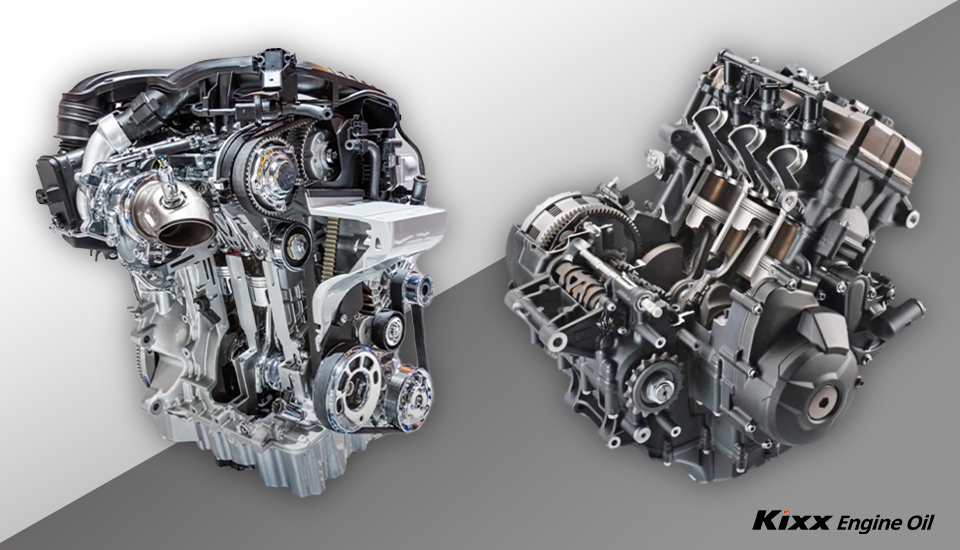

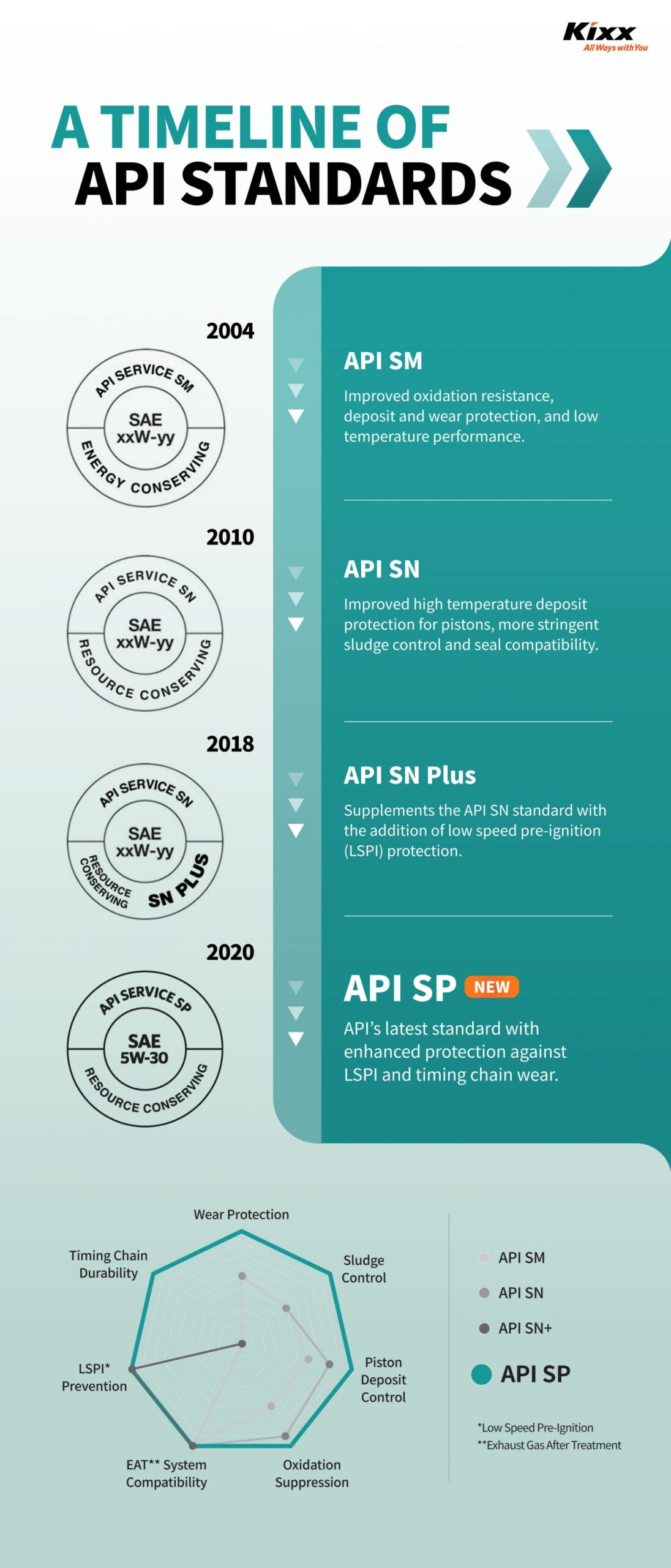

Oems have been under considerable pressure to offer engine that are more durable more fule efficint and produce less emmision than before .

Is Your Car Engine Oil Keeping Your Ride Smooth? Find Out Now!

Hey there, fellow car enthusiasts! Today, let's dive into a topic that's often overlooked but crucial for your vehicle's health and performance – Car Engine Oil. It's the lifeblood of your engine, and knowing the right questions to ask can make all the difference. So, let's roll up our sleeves and get to the nitty-gritty!

What's the Right Engine Oil for My Car?

Why Does the Grade (e.g., 10W-40) Matter?

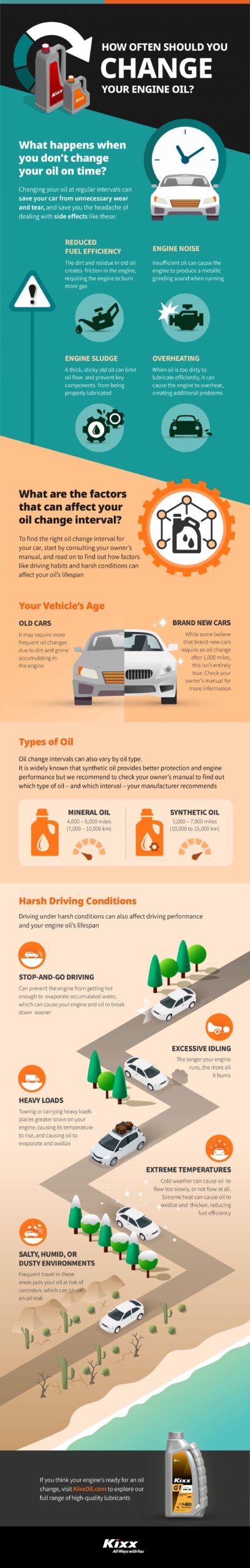

How Often Should I Change My Car's Engine Oil?

What Happens If I Use the Wrong Engine Oil?

How Does Engine Oil Quality Affect Performance?

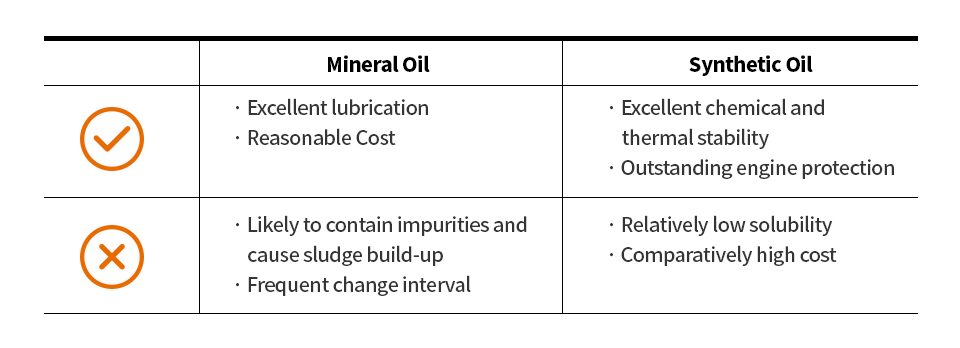

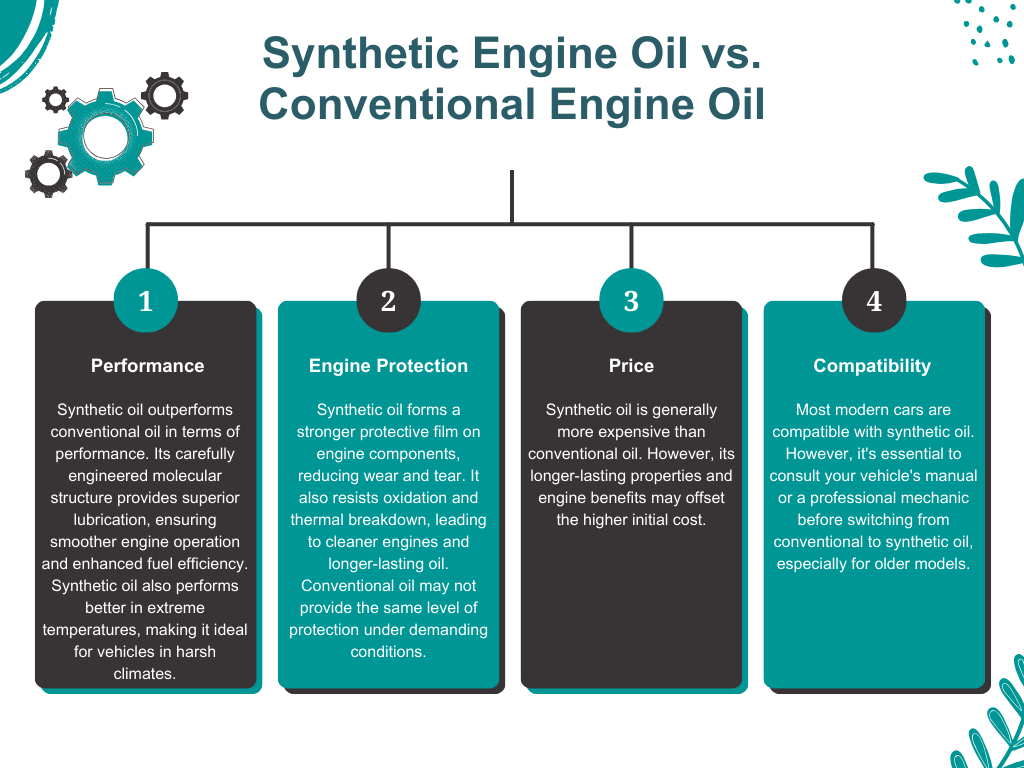

What's the Deal with Synthetic vs. Conventional Oil?

How Does Engine Oil Affect Fuel Efficiency?

What's the Deal with Car Engine Oil Prices?

Is DIY Oil Change Worth the Effort?

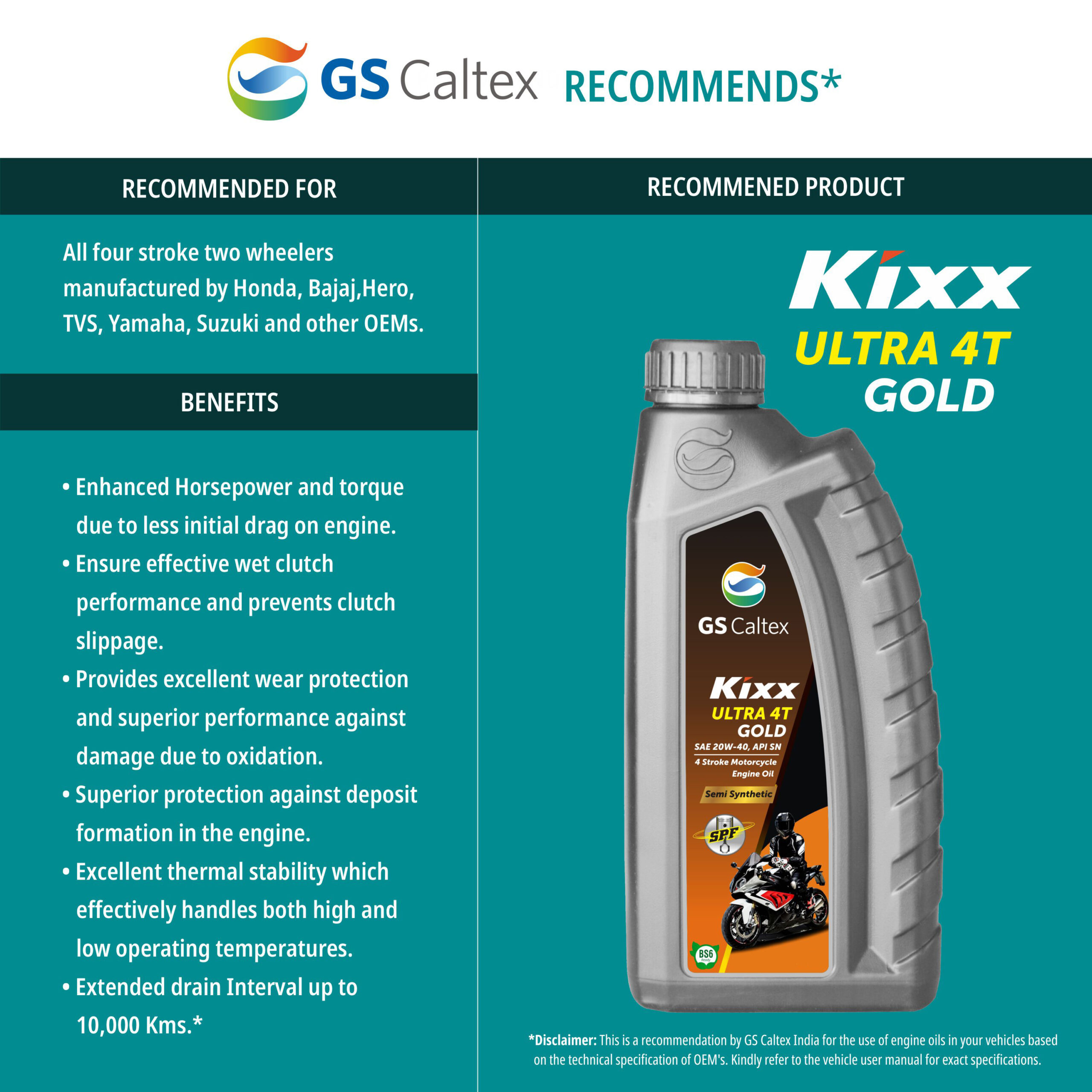

Choosing the right engine oil is like picking the perfect pair of shoes – it has to fit just right. Different cars have different needs, so consider factors like viscosity, additives, and manufacturer recommendations. A trusted brand like GS Caltex India offers a range of options, ensuring you find the best engine oil for your specific make and model.

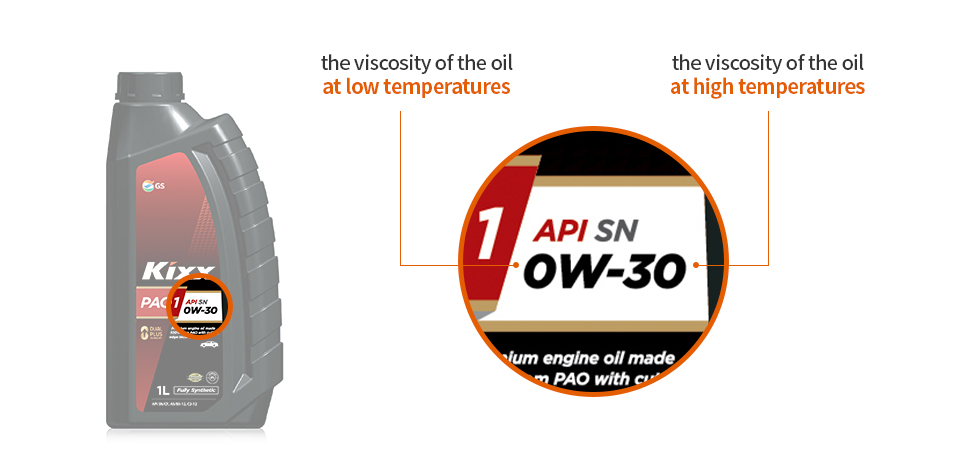

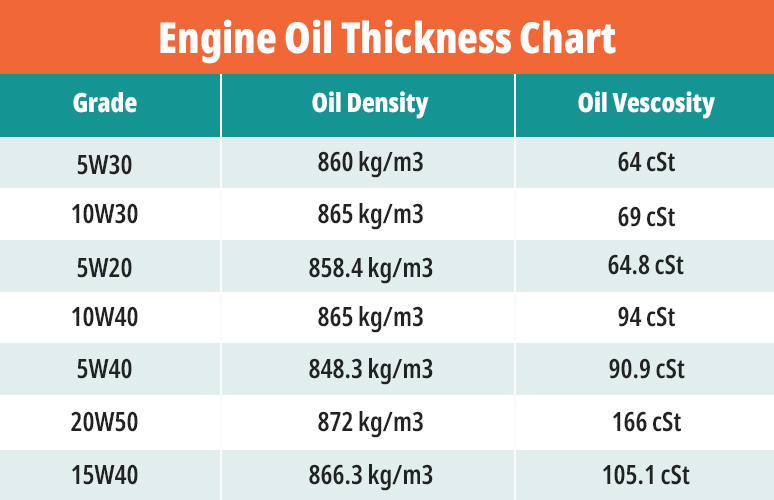

Ever wondered what those numbers on the engine oil bottle mean? They represent viscosity or the oil's thickness. For example, a 10W-40 oil is suitable for various temperatures. Understanding this can help your engine perform optimally, no matter the weather.

This one's a game-changer. Regular oil changes are like spa days for your engine. They keep it running smoothly and help extend its lifespan. The frequency depends on factors like driving habits, climate, and the type of oil used. GS Caltex India recommends a change every 3,000 to 5,000 miles for conventional oil and up to 15,000 miles for synthetic blends.

Picture this: you wouldn't wear a winter coat in the summer, right? Using the wrong engine oil can lead to reduced lubrication, increased wear and tear, and even engine damage. Always consult your owner's manual or a trusted mechanic to ensure you use the correct type.

Top-quality engine oil is like a symphony conductor, ensuring all engine components work harmoniously. It reduces friction, minimises wear, and prevents overheating. GS Caltex India takes pride in producing high-quality engine oils that meet and exceed industry standards, giving your car the performance boost it deserves.

It's like choosing between a gourmet meal and fast food. Synthetic oils offer superior performance, especially in extreme conditions, but come at a slightly higher price point. Conventional oils, while more budget-friendly, may require more frequent changes. Knowing the pros and cons can help you make an informed decision.

Ever wanted your car to be a bit more fuel-efficient? Well, it starts with the engine oil. High-quality oils reduce friction and improve engine efficiency, leading to better gas mileage. GS Caltex India's range of engine oils is designed with efficiency in mind, helping you go that extra mile.

Budget-conscious drivers, this one's for you. The Car Engine Oil Price can vary widely, but remember, quality trumps quantity. Investing in a reputable brand like GS Caltex India might mean a slightly higher upfront cost, but the long-term benefits of engine health and performance are well worth it.

Look no further than GS Caltex India. As one of the industry's leading engine lubricant manufacturers, they offer a wide range of high-quality engine oils tailored to your car's specific needs. Visit their website or consult a local dealer to find the perfect match for your vehicle.

Taking care of your is like investing in its longevity and performance. With the right knowledge and the best products from GS Caltex India, you're well on your way to ensuring your ride stays smooth for years. Don't hesitate – give your engine the love it deserves!

Find Your Car Engine OilReady to give your car the best engine oil it deserves? Visit GS Caltex India's website or contact a local dealer today! Your car will thank you later.

1. What's the difference between synthetic and conventional engine oil, and which one should I choose for my car?

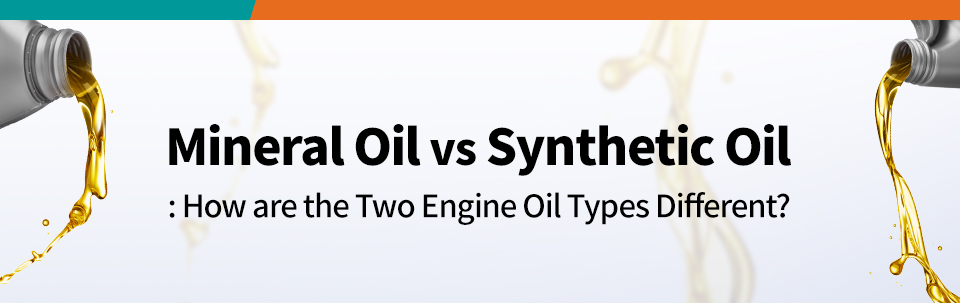

Synthetic oil is chemically engineered for uniform molecular structure, offering superior performance and protection. It provides better high-temperature stability and flows more smoothly at low temperatures, enhancing engine efficiency. Conventional oil, on the other hand, is derived directly from crude oil and is refined. It's more budget-friendly but may require more frequent changes.

The choice depends on your driving habits, climate, and the manufacturer's recommendations. Synthetic oil is the way to go if you want optimal performance, especially in extreme conditions. However, conventional oil can be a suitable choice if you're on a budget and don't drive under extreme conditions.

2. How often should I change my car's engine oil, and does it vary based on the type of oil I use?

The frequency of oil changes depends on several factors, including driving habits, climate, and the type of oil used.

Changing it every 3,000 to 5,000 miles is generally recommended for conventional oil. For synthetic blends or high-quality synthetic oils: They offer extended service intervals, often up to 15,000 miles. However, always refer to your car's owner's manual for manufacturer-specific recommendations.

3. Why is it important to choose the right engine oil viscosity, and how does it impact my car's performance?

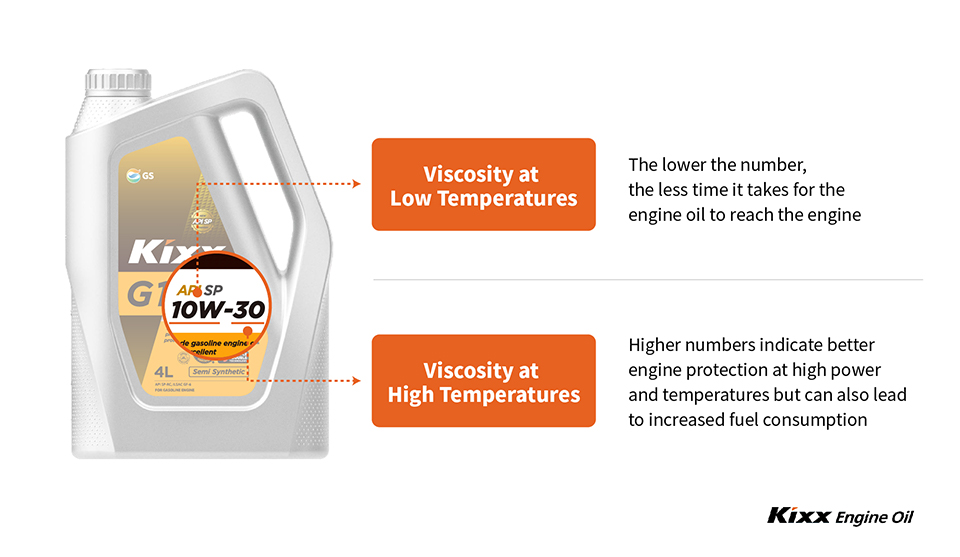

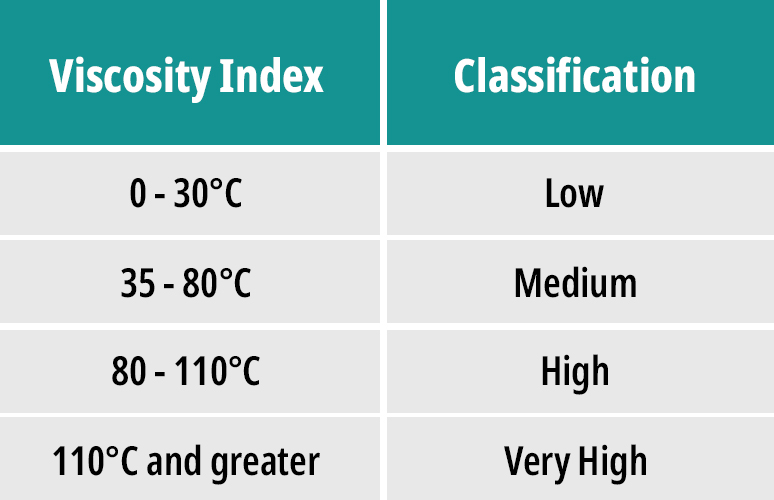

Viscosity refers to the oil's thickness or resistance to flow. It's represented by numbers like 10W-40. The 'W' represents winter, indicating how the oil performs in cold temperatures. The lower the number, the better it flows in cold weather. The second number indicates how it performs at operating temperature.

Choosing the right viscosity ensures proper lubrication and protection for your engine. Using an oil with the wrong viscosity can lead to issues like increased friction, wear, and even potential engine damage, particularly during startup in cold weather.

4. How does using high-quality engine oil affect my car's fuel efficiency and overall performance?

High-quality engine oil is crucial in enhancing fuel efficiency and overall performance. It reduces friction between moving parts, which in turn reduces energy loss. This means your engine operates more efficiently, potentially leading to better gas mileage. Additionally, top-quality oils have additives that clean and protect the engine, ensuring it performs at its best for longer.

5. Where can I find reliable information on which engine oil is best for my specific make and model of car?

A trusted source for such information is your car's owner's manual. It provides detailed specifications, including engine oil's recommended type and viscosity. Additionally, reputable engine lubricant manufacturers like GS Caltex India often provide online resources, including tools or guides on their websites, to help you find the right engine oil for your specific car make and model. You can also consult a local mechanic or an expert at an authorised service centre for personalised recommendations.

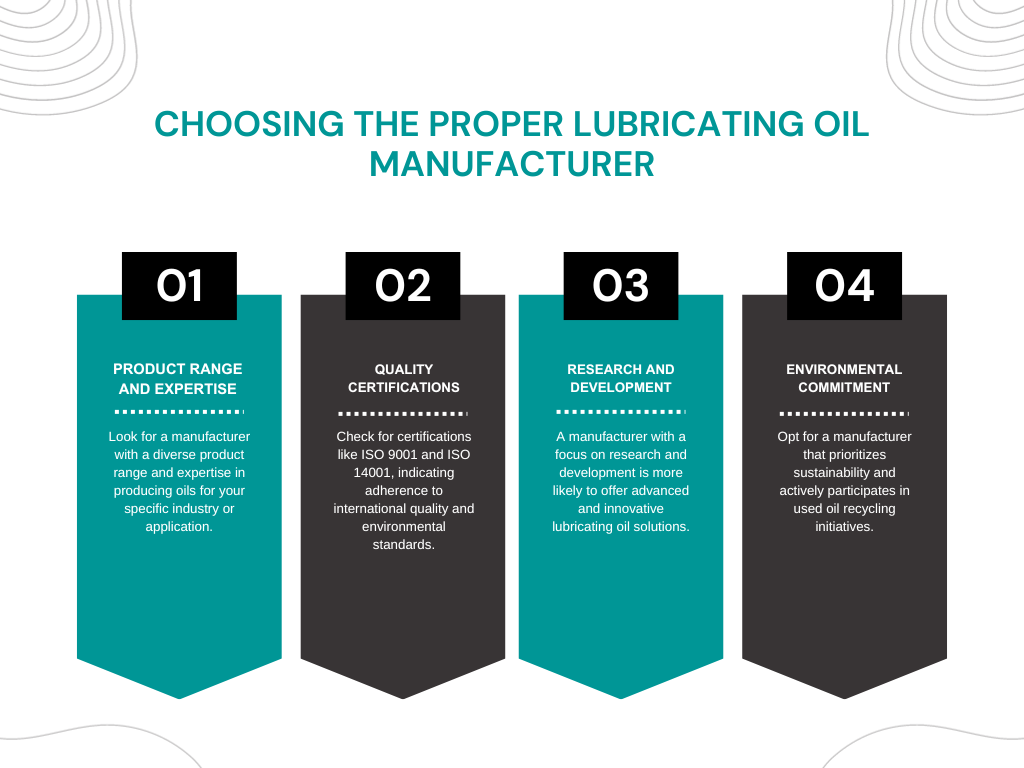

The lubricant industry in India is experiencing steady growth, presenting a promising opportunity for aspiring entrepreneurs who wish to become distributors in this sector. Becoming a lubricant distributor allows you to tap into a lucrative market and establish a successful business. In this informative and promotional blog post, we will outline the key steps to becoming a distributor in the lubricant business in India. By following these steps, you can embark on a rewarding journey in the lubricant industry and build a thriving distribution network.

Begin by conducting thorough research and analysis of the lubricant market in India. Identify potential competitors, understand market trends, and gain insights into customer preferences. This research will help you select the right lubricant brand to distribute and develop a strategic business plan.

Choose a reputable lubricant brand that aligns with your business goals and values. Consider factors such as brand reputation, product quality, range of offerings, marketing support, and pricing. Collaborating with a well-established brand will provide you with a competitive advantage and instill confidence in your customers.

Reach out to the lubricant manufacturer whose brand you wish to distribute. Initiate discussions and express your interest in becoming a distributor. Provide details about your business plan, market research, and your ability to meet the manufacturer's requirements. A strong business proposal and a convincing presentation can significantly enhance your chances of securing a distributorship.

Become a DistributorOnce you establish contact with the lubricant manufacturer, carefully review their distributorship requirements. This may include financial investments, infrastructure, storage facilities, transportation capabilities, and marketing commitments. Assess whether you meet these requirements and determine the feasibility of fulfilling them.

Create a comprehensive business plan that outlines your distribution strategy, target market, sales and marketing approach, operational processes, and financial projections. A well-crafted business plan will not only serve as a roadmap for your operations but also demonstrate your commitment and professionalism to the lubricant manufacturer.

Assess your financial capabilities and explore funding options if necessary. Seek financial assistance from banks, venture capitalists, or government schemes that support small businesses and entrepreneurs. Prepare a detailed financial projection to showcase the potential return on investment and attract potential investors or lenders.

Ensure that you have the necessary infrastructure, including storage facilities, warehousing space, and a distribution network. Obtain the required licenses and permits to operate as a lubricant distributor. Comply with all legal and regulatory requirements imposed by the government and industry authorities.

Finalize the distributorship agreement with the lubricant manufacturer. Review the terms and conditions, pricing policies, distribution territories, and any other relevant clauses. Seek legal advice if needed to ensure that the agreement is fair and beneficial to both parties.

Create a robust marketing and sales plan to promote your lubricant products effectively. Utilize various marketing channels such as digital marketing, advertising, trade shows, and partnerships with local mechanics, automobile workshops, and industrial clients. Build strong relationships with customers by offering excellent service and technical support.

Focus on providing exceptional customer service to build long-term relationships and ensure customer satisfaction. Offer technical guidance, timely delivery, and after-sales support to gain customer loyalty and trust. Happy customers can become your brand advocates, driving more business and referrals.

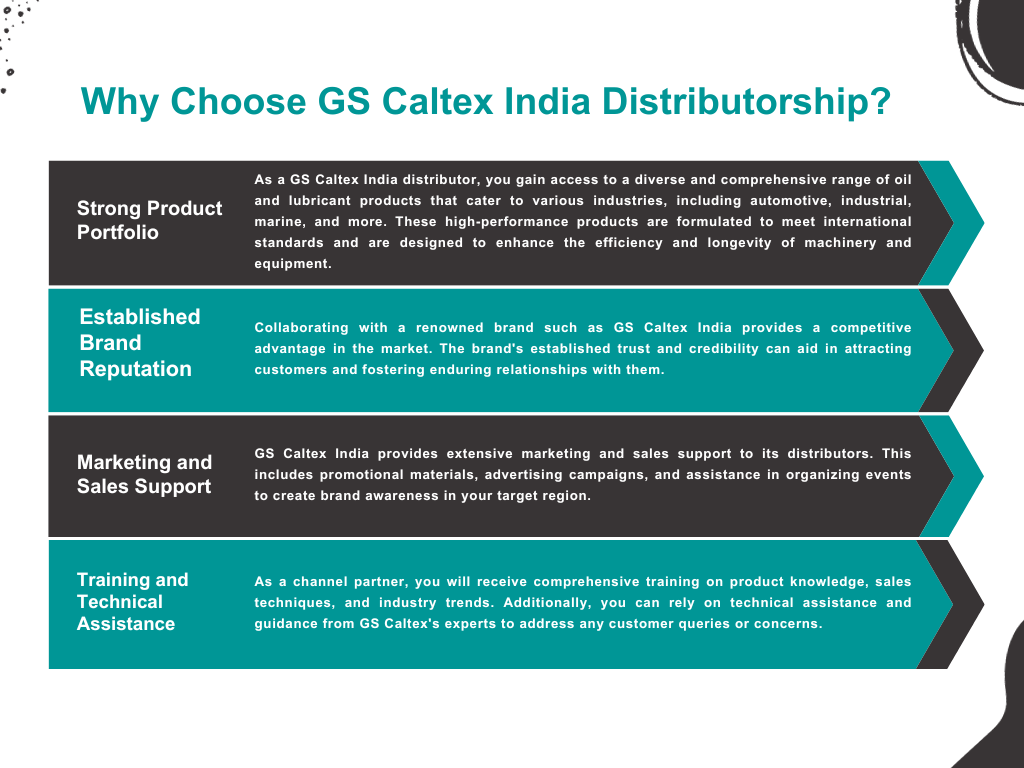

By choosing GS Caltex India as your distributor partner, you gain access to a wide range of superior lubricant products that cater to various industries and applications. GS Caltex's extensive product portfolio includes automotive lubricants, industrial lubricants, marine lubricants, and specialty lubricants, ensuring that you can meet the diverse needs of your customers.

Partnering with GS Caltex India also means benefiting from their strong brand reputation and comprehensive support system. They provide marketing support, technical training, and regular updates on industry trends and product advancements. With their guidance and resources, you can effectively promote and sell GS Caltex's lubricant products, gaining a competitive edge in the market.

Moreover, GS Caltex India places great emphasis on sustainability and environmental responsibility. Their lubricant formulations are designed to minimize environmental impact while delivering optimal performance. By aligning your business with GS Caltex India, you demonstrate your commitment to sustainable practices and meet the growing demand for eco-friendly lubricant solutions.

As a distributor-partner of GS Caltex India, you become part of a trusted network of professionals dedicated to delivering excellence in lubricant distribution. You can leverage their strong distribution channels, logistics support, and after-sales service to ensure seamless operations and customer satisfaction.

In conclusion, as you navigate the steps to become a distributor in the lubricant business in India, consider the advantages of partnering with GS Caltex India. Their industry expertise, exceptional product range, comprehensive support, and commitment to sustainability make them an ideal distributor partner. By joining forces with GS Caltex India, you can establish a successful lubricant distribution business, offering top-quality products and services to your customers. Together, you can drive growth, profitability, and customer satisfaction in the dynamic lubricant market of India.

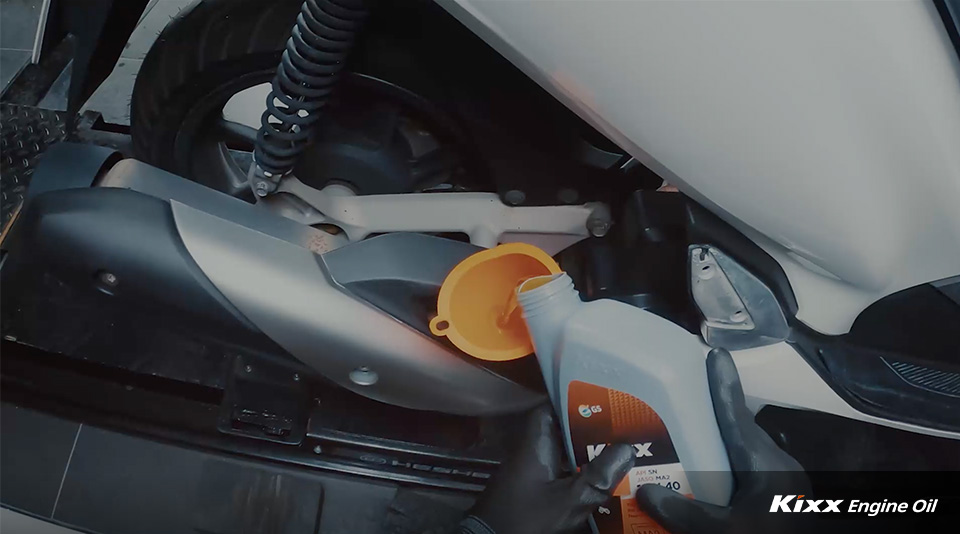

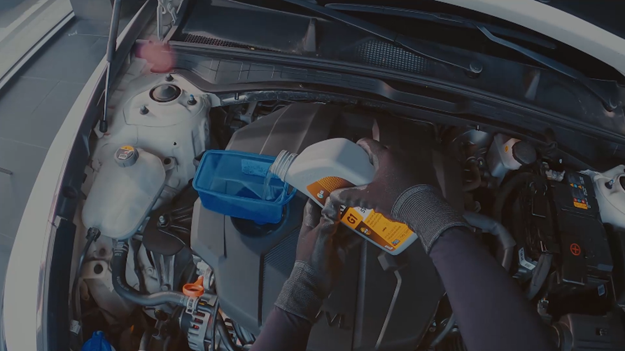

Changing engine oil at regular intervals not only helps in extracting the best performance and fuel efficiency, but also enhances the life of the engine and adds to the resale value of the vehicle

In the dynamic world of construction, the role of high-quality lubricants cannot be overstated. Construction equipment and machinery operate under demanding conditions, requiring reliable lubrication to ensure smooth operation, minimize downtime, and optimize performance. In this blog, we will explore five key facts about construction lubricants and shed light on the valuable contributions of GS Caltex India in this field.

Construction lubricants are specifically designed to meet the unique demands of heavy-duty equipment used in construction projects. They are engineered to withstand extreme pressures, high temperatures, and harsh environments. GS Caltex India, a leading provider of lubricant solutions, offers a wide range of construction lubricants formulated to enhance equipment performance and durability.

Construction machinery is subjected to significant wear and tear during operation. Construction lubricants play a crucial role in reducing friction and protecting vital components such as engines, gears, and hydraulic systems. GS Caltex India's construction lubricants are formulated with advanced additive technologies that provide exceptional wear protection, prolonging the lifespan of equipment and reducing maintenance costs.

Efficiency is paramount in the construction industry, where productivity and cost-effectiveness are crucial. High-quality construction lubricants, such as those offered by GS Caltex India, are designed to minimize energy losses caused by friction and optimize fuel economy. By reducing internal friction, these lubricants help maximize equipment performance, resulting in improved operational efficiency and reduced fuel consumption.

Construction sites often expose equipment to harsh elements, including moisture, dirt, and corrosive agents. Construction lubricants act as a protective barrier, guarding against corrosion and rust formation. GS Caltex India's construction lubricants are fortified with corrosion inhibitors, ensuring that critical components remain well-protected and prolonging the equipment's service life.

In today's environmentally conscious world, the construction industry is striving to reduce its ecological footprint. GS Caltex India is committed to sustainability and offers construction lubricants that meet or exceed environmental regulations. These lubricants are formulated with low-toxicity additives and are designed to minimize emissions, ensuring compliance with environmental standards without compromising performance.

As a leading player in the lubricant industry, GS Caltex India has a proven track record of delivering high-performance lubricants for construction applications. Their extensive range of construction lubricants is developed through rigorous research and development, adhering to the highest quality standards. With a deep understanding of the construction industry's unique challenges, GS Caltex India provides tailored lubricant solutions that enable construction companies to achieve optimal equipment performance, maximize productivity, and reduce maintenance costs.

Construction lubricants play a vital role in the efficiency, performance, and durability of construction equipment. GS Caltex India, with its expertise and commitment to excellence, offers a comprehensive range of construction lubricants tailored to meet the industry's specific requirements. By choosing GS Caltex India's construction lubricants, construction companies can benefit from superior wear protection, enhanced efficiency, corrosion prevention, and environmental compliance. Trust GS Caltex India to empower your construction projects with lubricant solutions that deliver exceptional performance and reliability.

Q1: How do construction lubricants empower efficiency?

Construction lubricants play a crucial role in enhancing the efficiency of construction equipment. By reducing friction and wear, they minimize energy losses and allow the machinery to operate at optimal performance levels. This leads to improved fuel efficiency, reduced downtime, and increased overall productivity on construction sites.

Q2: What are the key benefits of using heavy-duty lubricants in construction?

Heavy-duty lubricants offer several benefits in construction applications. They provide superior protection against wear and corrosion, extending the lifespan of equipment components. They also reduce maintenance requirements and associated costs. Additionally, these lubricants can handle extreme operating conditions, ensuring reliable performance even in high temperatures, heavy loads, and dusty environments.

Q3: How do construction lubricants contribute to equipment performance?

Construction lubricants contribute to equipment performance by providing effective lubrication to moving parts, minimizing friction and heat generation. This results in smoother operation, reduced noise, and vibration levels, which enhances the overall performance and reliability of construction machinery. Lubricants with appropriate viscosity and additives can also enhance the load-carrying capacity of the equipment.

Q4: What factors should be considered when selecting construction lubricants?

When selecting construction lubricants, several factors should be considered. These include the specific application and equipment type, operating conditions (such as temperature, load, and speed), manufacturer recommendations, and industry standards. It is important to choose lubricants that meet or exceed the equipment manufacturer's specifications to ensure optimal performance and longevity.

There are many choices when it comes to picking the appropriate oil for your car's engine. Our guide breaks down your choices to help you in the quest to...

When choosing the right oil for your car's engine, there are many options. Our guide dissects your options to assist you in your quest to change your oil.

Knowing your car's make and model is the first step in selecting the appropriate engine oil. In order to increase efficiency, new high-performance engines are being developed, and newer oil formulations have been created to support these advancements.

Consider the circumstances you typically encounter when driving, regardless of whether you live in a hot or cold climate or typically travel on paved or unpaved roads. Your car may be put under stress by a variety of factors, such as the need for frequent oil changes. When choosing the best type of motor oil for you, it's crucial to take into account the circumstances in which you live and drive.

When selecting the best engine oil, it's crucial to be aware of the weather and driving conditions.

You can select between mineral and synthetic engine oil once you are aware of the vehicle's make and model. Your choice of oil type is crucial because base oil makes up between 80% and 90% of an engine oil's composition. Knowing which type of oil best suits your car and driving style is essential because each has advantages and disadvantages.

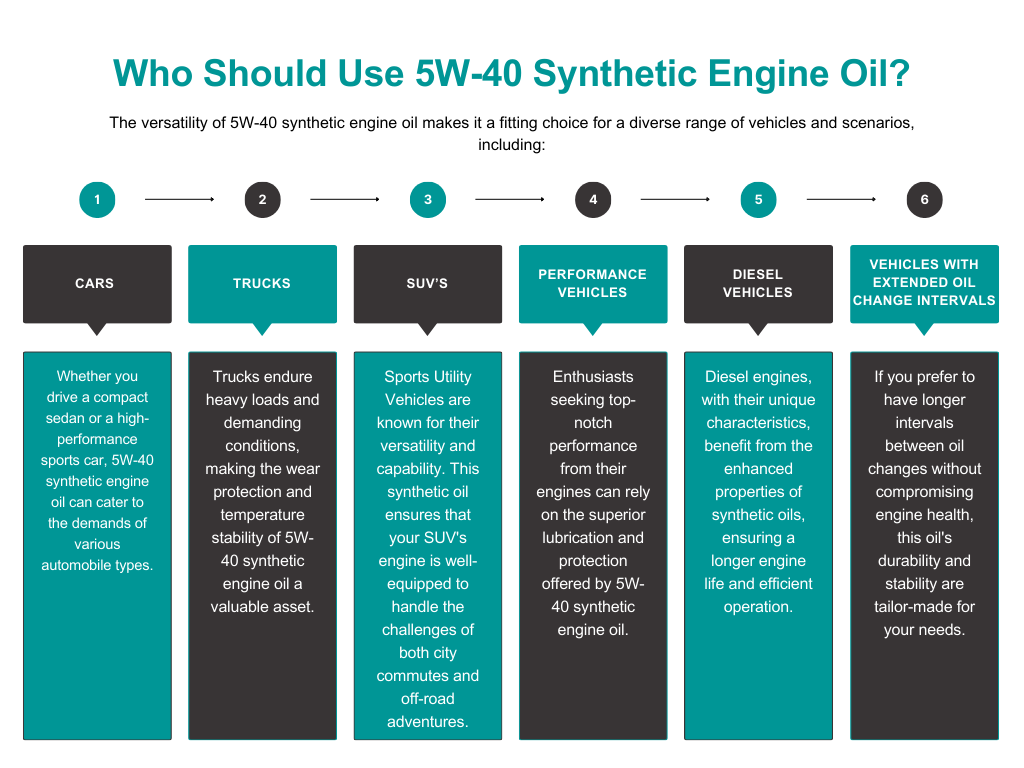

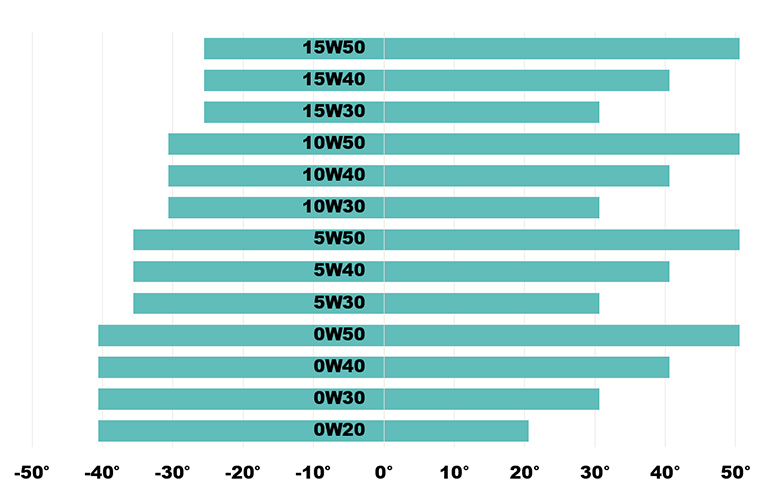

You might encounter confusing codes with numbers and letters on the packaging when comparing engine oil products. These show viscosity grade, an indication of the oil's flow resistance. When looking for the best engine oil, it is a crucial factor to take into account, along with the weather and driving conditions.

The viscosity of an oil is determined by two numbers. Winter is represented by the letter "W" at the end of the first number. This measurement has to do with how cold oil flows, like when an engine is starting up. The flow of oil at typical operating temperatures determines the second number.

In order to protect engine parts at colder temperatures, thin, low-viscosity oils flow more easily. In order to protect engines at higher temperatures, thick, high-viscosity oils are typically better at maintaining film strength. By checking the oil cap or the owner's manual, you can determine the proper viscosity for your car.

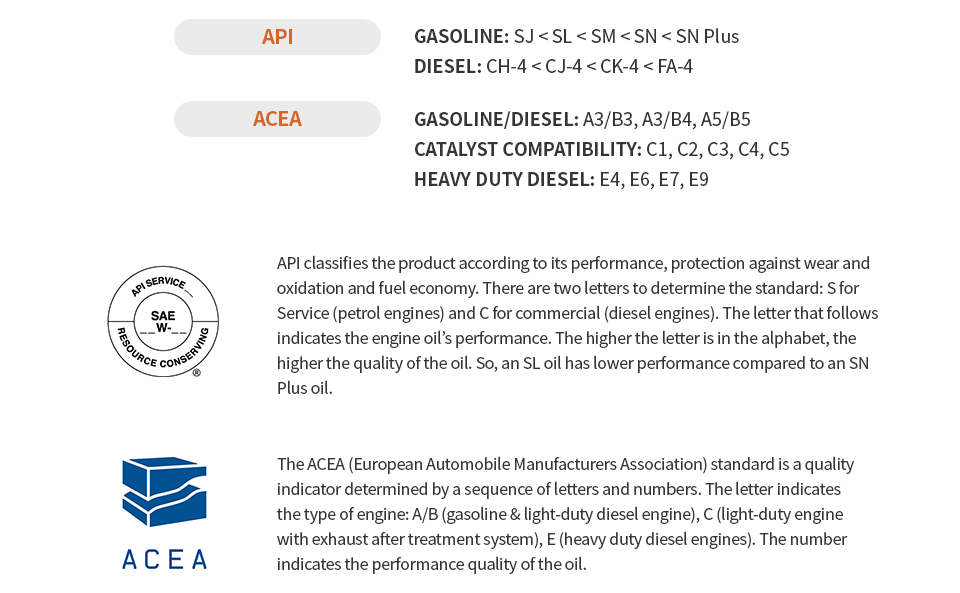

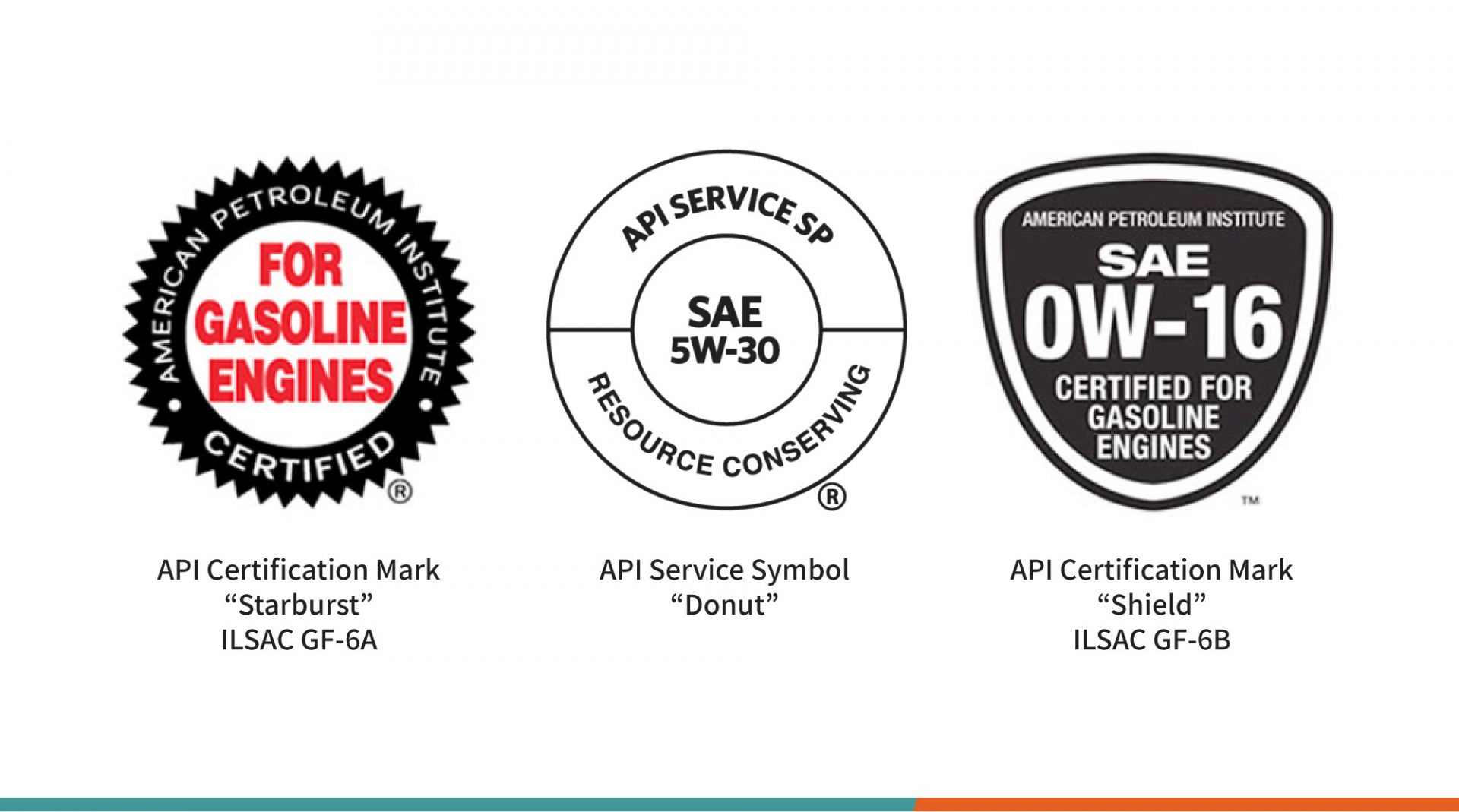

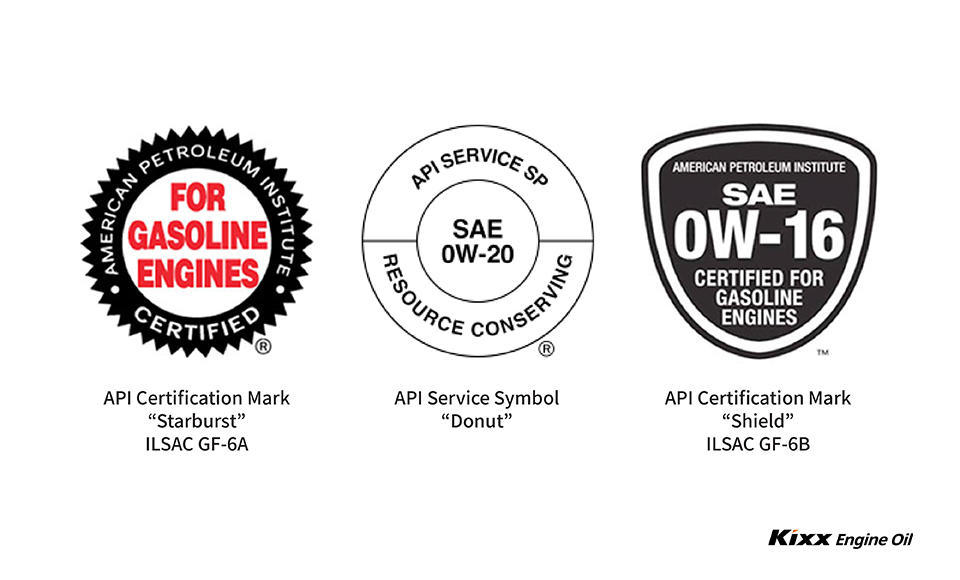

Engine oil standards are also indicated by various acronyms like API, ACEA, and ILSAC if you look more closely at the label. This indicates that the product satisfies or surpasses these organizations' standards. Specifications are crucial because they reveal the oil's performance and quality.

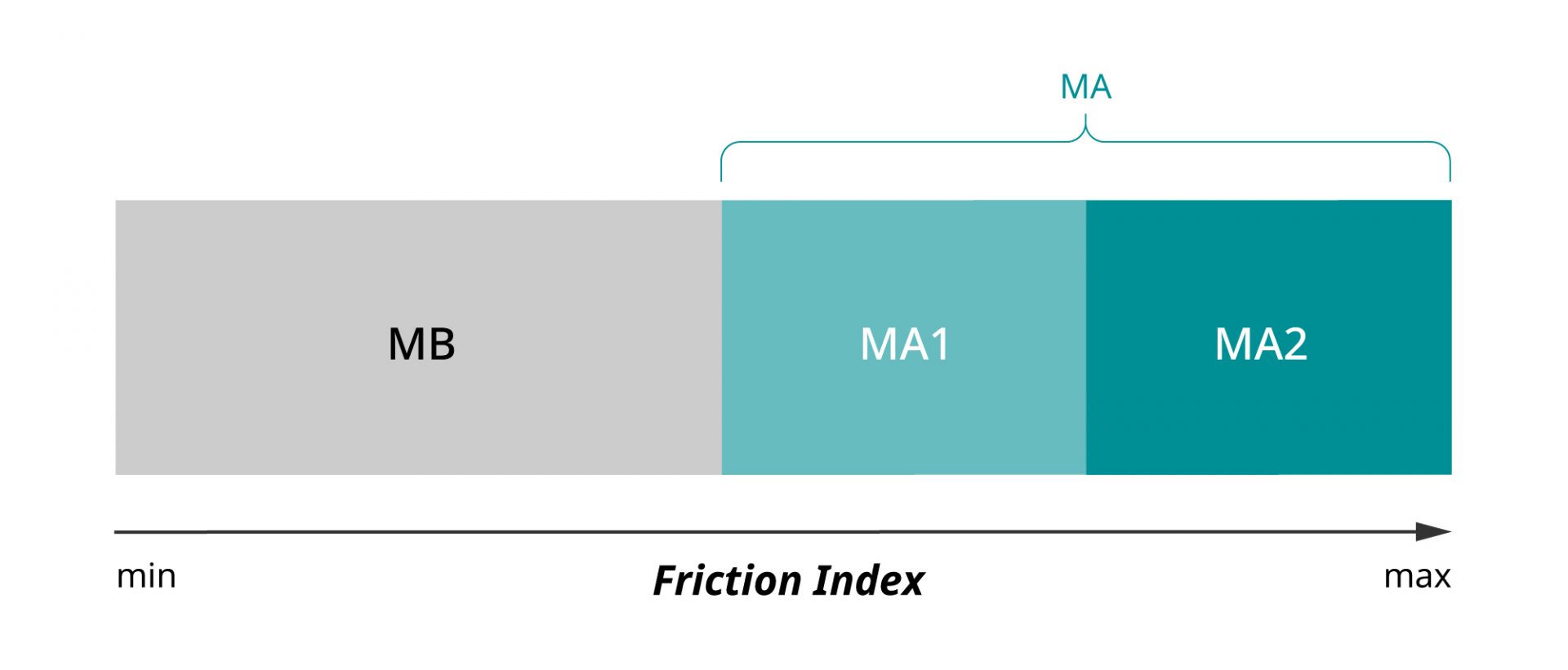

API( American Petroleum Institute) and ACEA ( Association des Constructeurs Européens) are the two most widely used standards.

It can be challenging to choose the right engine oil for your car, but doing so will increase engine life and improve engine performance. The next time you're looking for the best oil to improve your engine's performance, keep these 5 factors in mind.

There are many choices when it comes to picking the appropriate oil for your car’s engine. Our guide breaks down your choices to help you in the quest to change your oil.

There are two numbers that define the viscosity of an oil. The first number ends with the letter ‘W’, which stands for Winter. This measurement is related to how an oil flows when it is cold, such as on engine start-up. The second number is defined by how an oil flows at normal operating temperatures.

Thin, low viscosity oils flow easier to protect engine parts at colder temperature. Thick, high viscosity oils are typically better at maintaining film strength to protect engines at higher temperatures. You can find the right viscosity for your vehicle by looking on the oil cap or in the owner’s manual.

There are two numbers that define the viscosity of an oil. The first number ends with the letter ‘W’, which stands for Winter. This measurement is related to how an oil flows when it is cold, such as on engine start-up. The second number is defined by how an oil flows at normal operating temperatures.

Thin, low viscosity oils flow easier to protect engine parts at colder temperature. Thick, high viscosity oils are typically better at maintaining film strength to protect engines at higher temperatures. You can find the right viscosity for your vehicle by looking on the oil cap or in the owner’s manual.

Understanding engine oil and making the right choice for your car can be difficult but choosing the right engine oil will extend engine life and allow your engine to operate efficiently. Keep these 5 considerations in mind the next time you’re looking for the right oil to optimize the performance of your engine.

Understanding engine oil and making the right choice for your car can be difficult but choosing the right engine oil will extend engine life and allow your engine to operate efficiently. Keep these 5 considerations in mind the next time you’re looking for the right oil to optimize the performance of your engine.

Selecting an appropriate compressor oil is significant. It has a considerable impact on the overall performance of your machine. Compressor oils are excellent lubricants that help maintain your compressor. It reduces the wear and tear of your compressors. They are ideal for oil-flooded screws as well as vane compressors. Moreover, Compressor oil can efficiently decrease friction, reduce energy and maximise the life of a compressor. Hence, making the right choice and connecting with the lubricant manufacturers in India for quality Compressor oils is vital. Here’s a guide that can help you to choose the best compressor oil:

Compressor oils are of two types standard and synthetic. Both have distinct characteristics. It is essential to know the difference and features of each one of them before opting for a Compressor oil.

Compressor oils are one of the best things to improve the lifespan of your compressor. Replacing the Compressor oil regularly can help you maintain your machine better and reduce deposits. Study the components and specifications of your machine in detail to make the most suitable and smart choice. Look at the Best Compressor Oils from GS Caltex India, or Head to www.gscaltexindia.com for More info.

Ajax fiori engineering (india) private limited

How Mining Lubricants Pave the Way for Unparalleled Equipment Reliability and Safety!

Greetings, fellow enthusiasts of the engine oil realm! Today, I'm thrilled to dive into a topic that often flies under the radar: the indispensable role of mining lubricants in bolstering equipment reliability and safety. While we often associate lubricants with smooth operation, their impact on mining operations goes far beyond mere lubrication.

Allow me to guide you through a journey exploring the intricate web of benefits these Industrial Oils bring to the mining industry.

Call to Action: Elevate Your Mining Operations with GS Caltex India

Related Article:- Importance Of Lubricants In Mining Equipment

Why are industrial lubricants crucial in the mining industry?

Industrial lubricants are vital because they reduce friction, enhance operational efficiency, and extend the lifespan of mining equipment, ultimately contributing to safety and cost savings.

How do specialised formulations cater to the unique needs of mining operations?

Specialised formulations are designed to address the specific challenges posed by different mining equipment, environments, and applications. They ensure optimal performance under the most demanding conditions.

What role do mining lubricants play in environmental sustainability?

High-quality mining lubricants with low-friction formulations and advanced additives contribute to energy conservation and reduce waste, aligning with environmental stewardship efforts.

Why is GS Caltex India recognised as a leading engine lubricant manufacturer?

GS Caltex India is esteemed for its unwavering commitment to quality and innovation, offering a diverse range of meticulously crafted products tailored to meet the unique demands of mining operations.

How do industrial lubricants contribute to safety in mining?

Industrial Lubricants play a crucial role in preventing accidents and maintaining a secure working environment in the mining industry by ensuring smooth and predictable equipment operation. Embark on a journey of reliability, efficiency, and safety with the power of mining lubricants. Together, let's redefine excellence in mining operations. Choose GS Caltex India, and choose unmatched quality.

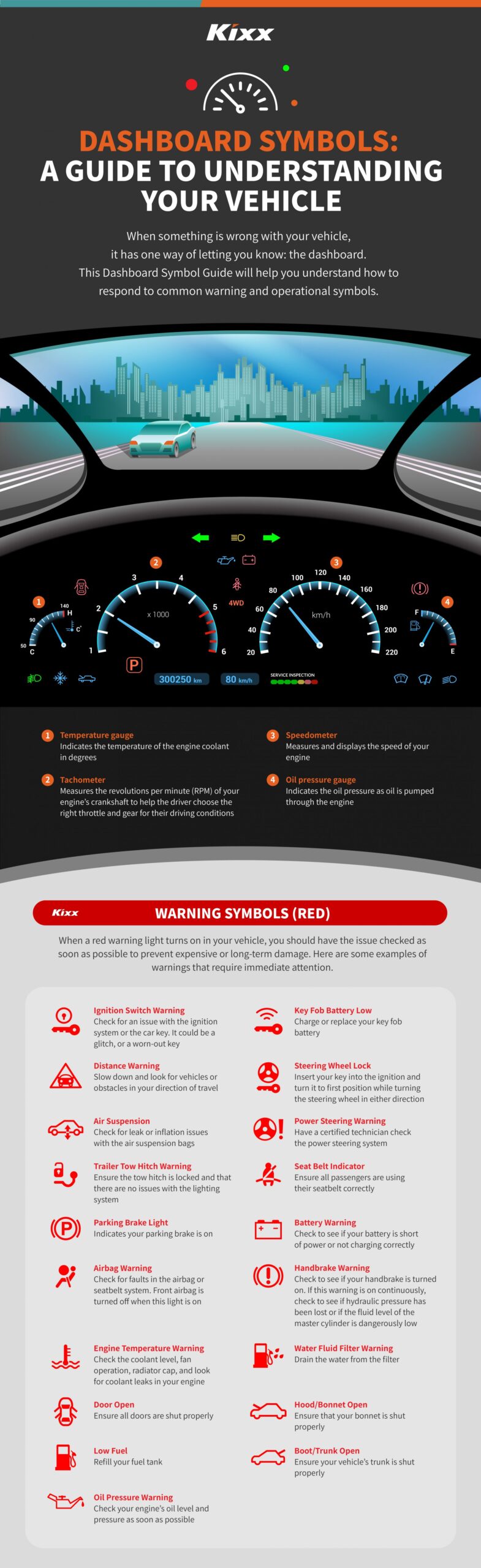

Why Engine Oil Matters: Your Car's Lifeline

Viscosity: The Thickness Matters

API and ACEA Ratings: Decoding Performance

Myth about Buying Engine Oil: How to Buy Engine Oil

Replacement Cycle of Engine Oil

Should you Replace Engine Oil if Driving a Car for Less Kms?

Lubrication: Engine oil lubricates moving parts within the engine, reducing friction and preventing wear and tear. Without proper lubrication, these components would grind against each other, leading to damage and reduced performance.

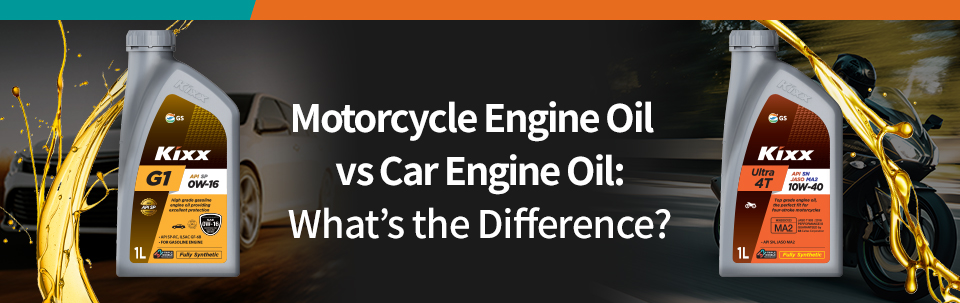

Lubrication: Engine oil lubricates moving parts within the engine, reducing friction and preventing wear and tear. Without proper lubrication, these components would grind against each other, leading to damage and reduced performance.Find Your Motorcycle Engine Oil

Most modern cars perform well with a 5W-30 or 5W-40 oil. However, it's essential to consult your car's owner's manual or the manufacturer's recommendations to ensure you're using the right viscosity for your specific vehicle.

Most modern cars perform well with a 5W-30 or 5W-40 oil. However, it's essential to consult your car's owner's manual or the manufacturer's recommendations to ensure you're using the right viscosity for your specific vehicle.

In conclusion, choosing the best engine oil for your petrol car in 2023 is a matter of understanding your vehicle's needs, following manufacturer recommendations, and considering trusted brands like GS Caltex India. Your car deserves the best care, and using the right engine oil will ensure it continues to run smoothly and efficiently for years to come. So, go ahead and give your car the attention it deserves and hit the road with confidence!

In conclusion, choosing the best engine oil for your petrol car in 2023 is a matter of understanding your vehicle's needs, following manufacturer recommendations, and considering trusted brands like GS Caltex India. Your car deserves the best care, and using the right engine oil will ensure it continues to run smoothly and efficiently for years to come. So, go ahead and give your car the attention it deserves and hit the road with confidence!

Q1: Is synthetic oil better than mineral oil for my petrol car?

In most cases, yes. Synthetic oil offers superior performance and protection.

Q2: Can I switch from mineral to synthetic oil?

Yes, you can, but consult your car's manual and a professional mechanic for guidance.

Q3: How often should I check my engine oil level?

It's a good practice to check it every few weeks, especially if you drive frequently.

Q4: Can I mix different brands of engine oil?

While it's best to stick to one brand, mixing oils is generally safe if they have the same viscosity and performance ratings.

Q5: Is it okay to use a higher viscosity oil than recommended?

It's not recommended, as it can affect engine performance and fuel efficiency.

Have you ever found yourself facing a low engine oil warning shortly after topping up? Maybe you’ve found oil leak stains spotting the ground where your car was parked....

Have you ever found yourself facing a low engine oil warning shortly after topping up? Maybe you’ve found oil leak stains spotting the ground where your car was parked. Pay close attention, because these are signs of car oil leak, and trying to drive a vehicle with a major oil leak – even a short distance – can do massive damage to your engine. Driving with low engine oil could mean depriving your vehicle of lubrication and stopping heat from circulating, leading to major drops in engine performance.

The good news is that most car oil leaks start small. In fact, a puddle between 1 to 2 inches in diameter, or what’s referred to as “seepage,” usually don’t represent an immediate threat to your engine.

Here are a few of the reasons your engine might be leaking oil unexpectedly.

More often than not, a sudden oil leak after oil change is caused by a malformed or cracked gasket. Gaskets are usually made of urethane or rubber, and they can harden over time. This can cause them to crack when they are exposed to sudden impact or extreme temperature changes, like the transition from a harsh winter to a hot summer. Since the gasket can no longer seal in the oil properly, it drips and spills out underneath your car – depleting engine oil levels slowly over time and leaving you with those shining puddles on the asphalt.

After examining your valves, the gasket is the first place to look for trouble when you suspect an oil leak.

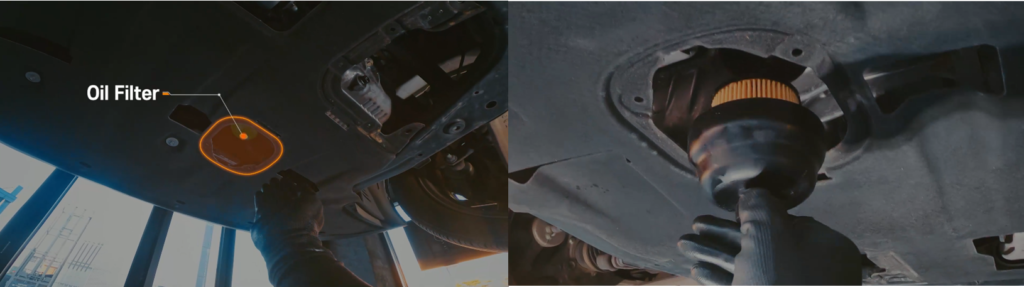

Another place to look when finding the source of an oil leak is the oil filter. Worn metal powders and other small particles often get mixed into the engine oil over time. It’s the oil filter’s job to parse these out and keep your engine oil supply free of contaminants. But when the oil filter is installed too loosely, it can start to cause leaks and allow oil to flow in places it’s not meant to be.

If your oil filter is leaking, try tightening it using your hands and a dry towel. If the oil filter still leaks, you may need to go deeper by removing the oil in your vehicle, replacing the oil filter, and then adding in new oil – essentially giving your vehicle an oil and a filter change all at once. Spraying lubricant around the base of the oil filter may tell you whether there any tiny leaks in the seal. If you do check the drain plug and oil filter but you don’t find any leaks, you may need to remove the oil pan and check the gasket.

Driving in highly saline places like along the coast of an ocean can also lead to more oil leaks than driving further inland. The salty conditions corrode the metal parts of your engine faster than usual, which can decrease the durability of your vehicle’s parts and lead to more frequent leaks. Of course, going to the beach once or twice during summer won’t cause you any problems. But if you happen to live in a coastal area, park near the beach, or drive seaside roads frequently, it may be beneficial to pay closer attention to what’s going on under your car.

Long drives in cold areas or excessive acceleration at cold temperatures can also put additional strain on the gasket and other systems, eventually leading to reduced durability and potentially resulting in engine oil leaks.

If you find signs of an oil leak, the best thing you can do is find the culprit right away. After discovering the faulty part, you should have it replaced or repaired immediately. In extreme situations you may consider using an engine oil stop, but this is only a temporary measure and won’t resolve the root cause of the problem.

Since small leaks can be tough to find, regular engine inspection and maintenance is your best way to prevent surprises and stop minor car oil leaks from becoming major ones. Checking your engine oil levels through the engine oil gauge and inspecting the bottom of your car when changing your engine oil can also go a long way to helping you avoid leaks and keep your vehicle running safely for longer.

Have you ever experienced a warning that your engine is running low soon after topping up? Perhaps there are oil leak stains all over the place where your car was parked. Pay close attention because these are warning signs of a car oil leak, and trying to operate your car while it has one can seriously harm your engine. Low engine oil consumption may result in your car losing lubrication and preventing heat from flowing, which will significantly reduce engine performance.

The majority of car oil leaks begin small, which is good news. In actuality, a "seepage," or puddle between one and two inches in diameter, typically poses no immediate threat to your engine.

A malformed or cracked gasket is frequently to blame for an unexpected oil leak after an oil change. Typically made of rubber or urethane, gaskets can become more durable over time. When they are exposed to sudden impact or drastic temperature changes, such as the change from a harsh winter to an intense summer, this can lead to cracking. Because the gasket is unable to properly seal in the oil, it drips and spills out from under your car, gradually lowering the level of engine oil and leaving you with those gleaming puddles.

When you suspect an oil leak, the gasket should be the first place you check for trouble after checking your valves.

The oil filter is another place to look when determining where an oil leak originates. Over time, engine oil frequently contains small particles and worn metal powders. The oil filter's responsibility is to remove these impurities and maintain a clean supply of engine oil. However, if the oil filter is applied too loosely, leaks may develop, and oil may begin to flow where it should not.

Try using your hands and a dry towel to tighten your oil filter if it is leaking. If your car's oil filter continues to leak, you might need to go a step further by having the oil removed, replaced, and then re-inserting it. This would essentially involve replacing both your oil and filter at once. If there are any minor leaks in the seal, you can check by sprinkling lubricant around the oil filter's base. You might need to take out the oil pan and check the gasket if the drain plug and oil filter are checked, but there are no leaks.

More oil leaks can result from driving near an ocean's coast than farther inland in areas with high salinities. The salty environment causes your engine's metal components to corrode more quickly than usual, which can shorten the life of your vehicle's components and cause leaks more frequently. Of course, visiting the beach occasionally during the summer will not be a problem for you. However, it might be advantageous to pay closer attention to what's happening under your car if you live near the coast, park close to the beach, or frequently drive along seaside roads.

The gasket and other systems may also be put under additional stress by long drives in cold weather or excessive acceleration at low temperatures, which can eventually reduce the durability and lead to engine oil leaks.

The best course of action if you notice any indications of an oil leak is to immediately identify the source. You should replace or repair the defective component as soon as you find it. You might think about turning off the engine oil in dire circumstances, but doing so will not solve the problem's underlying causes; it is only a short-term solution.

Regular engine inspection and maintenance is the best way to avoid surprises and prevent minor car oil leaks from developing into major ones because small ones can be difficult to find. You can prevent leaks and keep your car running safely for longer by checking the engine oil levels through the gauge and by looking at the bottom of the car when changing the oil.

Compressor oil plays a crucial role in maintaining the performance and reliability of industrial air compressors. It provides lubrication, cooling, and sealing properties to ensure smooth operation and extend the lifespan of the equipment. In this blog, we will delve into the world of compressor oil, exploring its features, benefits, applications, typical properties, and important health and safety considerations.

TCompressor oil is designed to withstand high temperatures generated during compression, ensuring consistent lubrication and protection against oxidation.

Compressor oil forms a thin protective film on the moving parts of the compressor, reducing friction and wear. It helps prevent surface damage, enhancing the efficiency and longevity of the equipment.

To maintain optimal compressor performance, compressor oil is formulated with anti-foaming additives. These additives prevent the formation of foam, ensuring efficient lubrication and preventing damage caused by air entrainment.

Compressor oil contains anti-corrosion additives that protect metal surfaces from moisture and corrosive elements. This helps prevent rust formation, extending the life of the compressor.

By providing proper lubrication and reducing friction, Compressor oil helps optimize equipment efficiency. It minimizes energy losses, allowing the compressor to operate at peak performance levels.

The use of high-quality compressor oil helps minimize wear and tear on the compressor's moving parts. This extends the equipment's lifespan and reduces the frequency of maintenance and repair.

Compressor oil with low friction characteristics helps reduce energy consumption. By minimizing internal losses and maximizing equipment performance, it contributes to energy savings and cost-effectiveness.

Compressor oil acts as a barrier against contaminants, preventing them from entering the compressor and causing damage. It helps maintain clean and efficient operation, reducing the risk of costly breakdowns.

Compressor oils exhibit various properties that make them suitable for demanding compressor applications. These properties include:

Compressor oils have specific viscosity grades that ensure optimal flow and lubrication under operating conditions, ranging from low to high viscosity depending on the application.

The flash point of compressor oil represents the temperature at which it emits vapor that can ignite in the presence of an open flame. Compressor oil have high flash points, ensuring safe operation.

The pour point is the lowest temperature at which the compressor oil can flow. Compressor oils with low pour points can withstand colder environments, ensuring reliable performance.

When handling compressor oil, it is essential to follow proper health and safety guidelines, including:

Use appropriate PPE, such as gloves and safety glasses, when handling Compressor oil to prevent skin contact and eye irritation. Follow the manufacturer's recommendations for PPE usage.

Store compressor oil in a cool, dry, and well-ventilated area away from direct sunlight and ignition sources. Follow proper handling procedures to avoid spills and leaks, and dispose of used oil according to local regulations.

Ensure that the compressor oil selected is compatible with the materials used in the compressor system. Incompatible oils can lead to equipment damage or failure.

Schedule routine maintenance and oil analysis to monitor the condition of the compressor oil. Regular oil changes and filter replacements help maintain optimal performance and prevent contamination.

When it comes to high-quality compressor oil, GS Caltex India stands out as a reliable and trusted partner. Their commitment to excellence and industry-leading products make them a preferred choice in the market. Here's why GS Caltex India should be your go-to source for compressor oil:

GS Caltex India offers a comprehensive range of compressor oils tailored to meet diverse industry needs. Their products are formulated using advanced technology and adhere to stringent quality standards.

Compressor oils from GS Caltex India deliver outstanding performance, ensuring smooth operation and superior protection for your compressors. Their oils are designed to handle high temperatures, resist oxidation, and provide long-lasting lubrication.

GS Caltex India understands that each compressor application is unique. Their experienced team can provide personalized lubrication solutions tailored to your specific requirements, ensuring optimal performance and efficiency.

With a deep understanding of compressor systems and lubrication technology, GS Caltex India's technical experts can offer valuable insights and guidance. They are dedicated to helping customers achieve the best results and maximize the lifespan of their equipment.

GS Caltex India prioritizes sustainability in their operations and product development. They strive to minimize the environmental impact of their products while maintaining high performance and efficiency.

When it comes to selecting compressor oil for your industrial applications, choosing a reliable and high-quality product is paramount. GS Caltex India, with its extensive product range, exceptional performance, customized solutions, technical expertise, and commitment to sustainability, emerges as a top choice. Trust GS Caltex India for all your compressor oil needs and experience the reliability, efficiency, and longevity that their products offer.

Q1: What are the features of compressor oil?

Compressor oil typically possesses the following features:

Q2: What are the benefits of using compressor oil?

The use of compressor oil offers several benefits, including:

Q3: In which applications is compressor oil used?

Compressor oil is used in various applications that employ air compressors, such as:

Q4: Can compressor oil be used interchangeably with other lubricants?

No, compressor oil is specifically designed for air compressors and should not be used interchangeably with other lubricants such as engine oil or hydraulic oil. The unique formulation of compressor oil ensures it can handle the specific demands of compressors, including high temperatures, moisture, and air compression requirements.

Q5: How often should compressor oil be changed?

The frequency of oil changes depends on various factors, including the compressor type, operating conditions, and manufacturer's recommendations. It is generally recommended to follow the equipment manufacturer's guidelines or consult the compressor oil supplier for specific recommendations on oil change intervals.

Q6: Can I mix different brands or types of compressor oil?

It is generally recommended to avoid mixing different brands or types of compressor oil unless approved by the manufacturer or stated otherwise in the equipment manual. Mixing oils can lead to compatibility issues, reduced performance, and potential damage to the compressor. It is best to use the same type and brand of oil recommended by the manufacturer.

Q7: How should compressor oil be stored?

Compressor oil should be stored in a cool, dry, and well-ventilated area, away from direct sunlight, heat sources, and ignition hazards. Proper storage conditions help maintain the oil's quality and prevent contamination. It is important to follow the manufacturer's recommendations for storage and handling of compressor oil.

Q8: Are there different types of compressor oil available?

Yes, there are various types of compressor oil available, including mineral-based oils, synthetic oils, and semi-synthetic blends. The choice of compressor oil depends on factors such as compressor type, operating conditions, and manufacturer recommendations. It is essential to select the appropriate oil type to ensure optimal performance and longevity of the compressor.

Q9: How can I determine the right compressor oil for my equipment?

To determine the right compressor oil for your equipment, it is crucial to consult the compressor manufacturer's recommendations and specifications provided in the equipment manual. They will specify the required viscosity, performance specifications, and any particular considerations for your compressor model. Additionally, you can seek guidance from compressor oil suppliers or consult with experts familiar with compressor systems.

This is the first time we participated in Bauma as a direct exhibitor and it has been quite a satisfying experience for us with the response we got during the 4 days of the event.

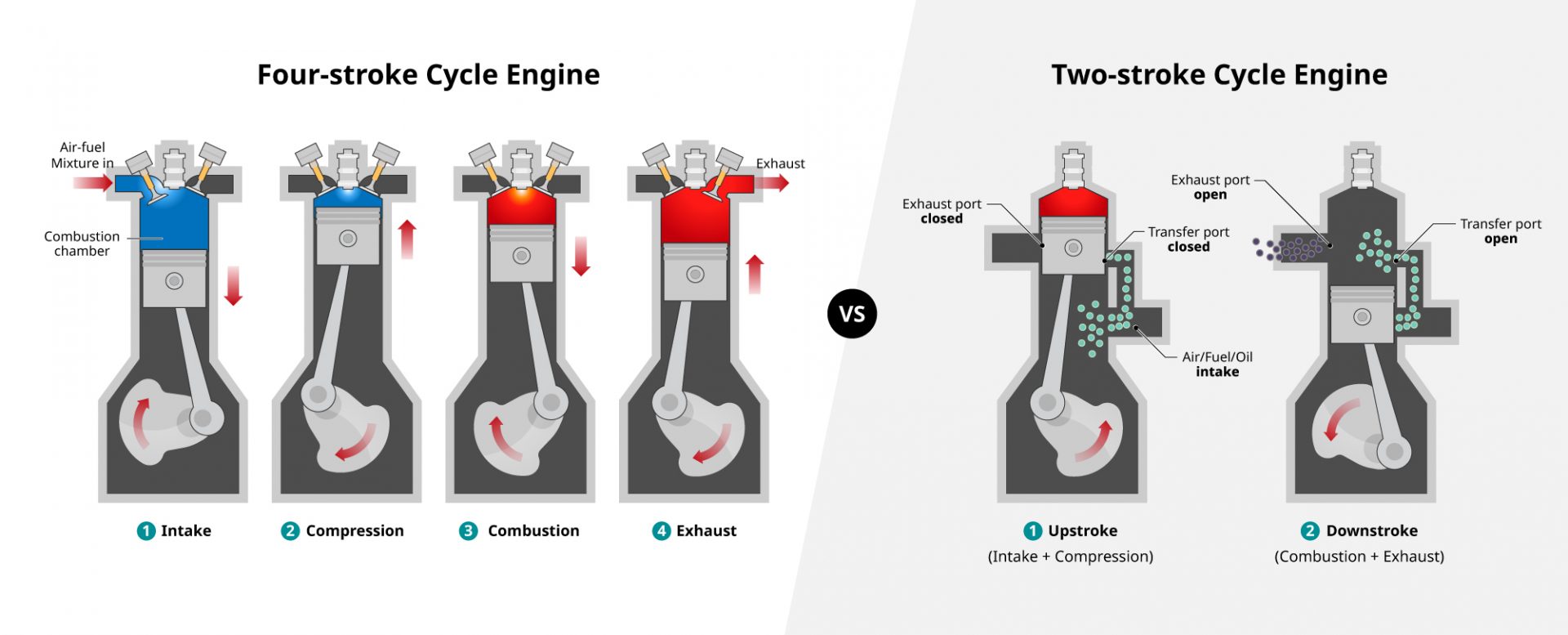

Automobile industries occupy an integral part of our business and contribute significantly to the development of society. However, the foundation of this automobile industry depends on fuels. The increasing population is imposing stress on the availability of the natural reserves of fuels like coal, petroleum, and natural gas. It is also increasing the pollution levels and, to combat this issue, people are getting inclined towards an alternative source of energy.

Conventional Energy SourcesThe conventional sources of energy for automobiles were traditionally petrol. However, in the era of development, people are focusing on the use of diesel and other energy forms for cars, bikes, and other automobiles. Debate is still on about the benefits and use of petrol and diesel engine oil. Irrespective of the nature of the engine oils, the importance of diesel engine oils never goes out of trend. However, some popular myths surround the minds of people these days. It might affect the net productivity of the engine oils.

Some Myths Surrounding Diesel Engine OilNot to Switch Brands - Most people remain loyal to a single diesel oil brand. However, it is not the best decision as the demands of your engine also change with time and climatic conditions. Many people also believe that changing the brand of the diesel engine oil, the efficacy, and the oil pressure also changes. However, it is not true. You should understand your engine specifications while choosing the diesel. If the diesel is not at par with the OEM specifications, it might not cater to your engine needs.

Not Choosing Synthetic Oils - Many people remain in a dilemma to pick up the synthetic diesel oils for your engine. They believe that mineral oils are best for the engine. However, if you know the components present in the synthetic oils, you will remain assured that they will protect your engine better. Moreover, the problem of seal compatibility issues is not there.

Checking Diesel Condition - The diesel engine oils may absorb many dust particles, pollutants, and other gases during their performance. Many people will make a decision about the condition of the diesel oil by looking at the colour. According to most people, the black colour signifies the low quality of the diesel. However, it is opposite to the belief. The dark colour of the diesel oil gives better efficacy of the oil on the engine performance. It is better to get an expert to perform the diesel examination.

Accumulation of Dirt in the Diesel Engine Oils - There is also a myth that only dust, and metal particles followed by dust, soot, and other pollutants accumulate in the diesel oil. However, it is not true. Apart from the accumulating pollutants, the oxidation temperature of the engine oils also decreases. It increases friction on the engine. The addition of additives might not help increase the life of your engine oil. You need to change and replace the engine diesel oil to maintain the engine efficacy.

There are several advantages associated with the use of diesel engine oil. It gives a long life to the engine in a cost-effective manner. The diesel oil tends to cool and prevent excess engine friction—a lower engine temperature helps maintain engine productivity. Kixx Dynamic Gold SAE 15W-40, API CH-4 is one such product from GS Caltex India Pvt Ltd which has exceptional protection and performance in all weather conditions

Happy driving!

How often should I change my car's engine oil?

Generally, it's recommended to change your car's engine oil every 3,000 to 5,000 miles, but refer to your car's manual for specific intervals.

Can I use any engine oil for my car?

It's crucial to use the type and grade of engine oil recommended by your car's manufacturer. GS Caltex India offers a wide range of high-quality engine oils suitable for various car models.

What happens if I don't change my car's engine oil?

Neglecting regular oil changes can lead to decreased fuel efficiency, increased emissions, and even engine damage due to excess wear and tear.

How can I tell if my car needs an oil change?

Look for signs like dark, gritty oil on the dipstick, decreased fuel efficiency, or strange engine noises. Regular oil checks are essential for preventative maintenance.

What's the difference between synthetic and conventional engine oil?

Synthetic oil offers superior high-temperature stability and overall performance compared to conventional oil. However, always use the type recommended by your car's manufacturer.

The Heartbeat of Your Car: Engine Oil 💓

Decoding Synthetic Engine Oil 💡

GS Caltex India: Your Engine's Best Friend 🇮🇳

When it comes to choosing the right synthetic engine oil for your car, look no further than GS Caltex India. As one of the best engine oil manufacturers in the industry, GS Caltex India offers a wide range of high-quality synthetic oils that cater to the specific needs of your vehicle.

Here are some key reasons why GS Caltex India stands out:

When it comes to choosing the right synthetic engine oil for your car, look no further than GS Caltex India. As one of the best engine oil manufacturers in the industry, GS Caltex India offers a wide range of high-quality synthetic oils that cater to the specific needs of your vehicle.

Here are some key reasons why GS Caltex India stands out:

Q1: Is synthetic engine oil suitable for all cars?

While synthetic engine oil can benefit most cars, it's essential to consult your car's manual or a trusted mechanic to ensure it's the right choice for your specific vehicle.

Q2: Can I switch from conventional oil to synthetic oil?

Yes, you can make the switch. However, it's essential to consult with a professional to ensure a smooth transition, as synthetic oil may have different compatibility requirements.

Q3: Does using synthetic engine oil void my car's warranty?

Not necessarily. Most car manufacturers approve the use of synthetic engine oil. Still, it's crucial to follow the manufacturer's recommendations to maintain your warranty.

Why is the viscosity of engine oil so important? The most important thing to consider when choosing an engine oil is viscosity – the thickness or flow of oil. Depending...

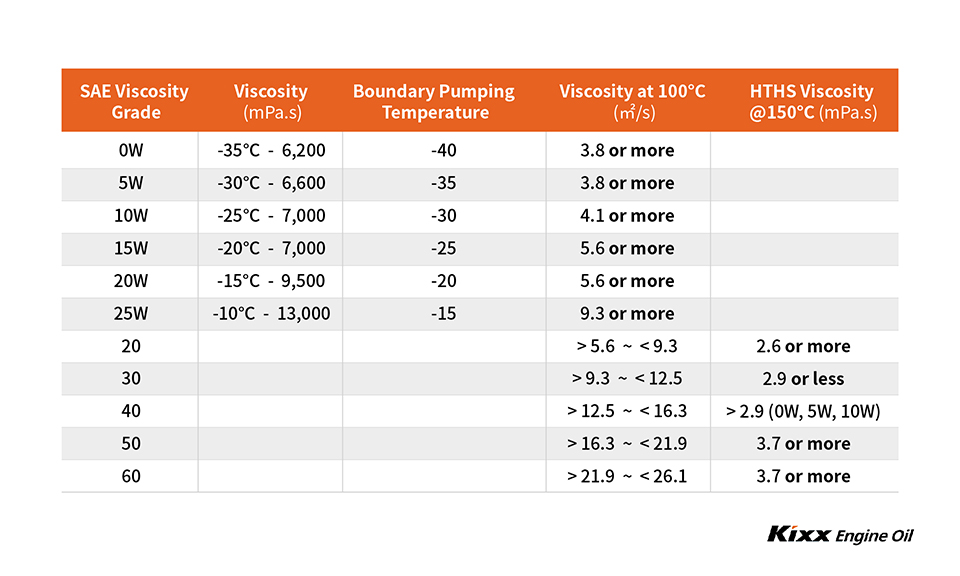

Let’s look at an example by breaking down the characteristics of a 10W-30 engine oil. According to the table, multi-grade oils starting with 10W have a viscosity equivalent to 7,000 mPa.s or less at -25 degrees Celsius with the boundary pumping temperature equivalent to -30 degrees Celsius or below. Oils with SAE viscosity grades ending in 30 have a viscosity between 9.3 and 12.5 m²/s at 100 degrees Celsius with an HTHS viscosity (high temperature high shear) of 2.9 mPa.s or less at 150 degrees Celsius. This means that the engine oil will be relatively thin at low temperatures to improve startability during cold weather and will not be too thick at high temperatures in order to form a lubricating oil film. Because the viscosity of this oil is adaptable based on temperature, 10W-30 grade oil is suitable for use in places where the temperature difference is significant.

Let’s look at an example by breaking down the characteristics of a 10W-30 engine oil. According to the table, multi-grade oils starting with 10W have a viscosity equivalent to 7,000 mPa.s or less at -25 degrees Celsius with the boundary pumping temperature equivalent to -30 degrees Celsius or below. Oils with SAE viscosity grades ending in 30 have a viscosity between 9.3 and 12.5 m²/s at 100 degrees Celsius with an HTHS viscosity (high temperature high shear) of 2.9 mPa.s or less at 150 degrees Celsius. This means that the engine oil will be relatively thin at low temperatures to improve startability during cold weather and will not be too thick at high temperatures in order to form a lubricating oil film. Because the viscosity of this oil is adaptable based on temperature, 10W-30 grade oil is suitable for use in places where the temperature difference is significant.

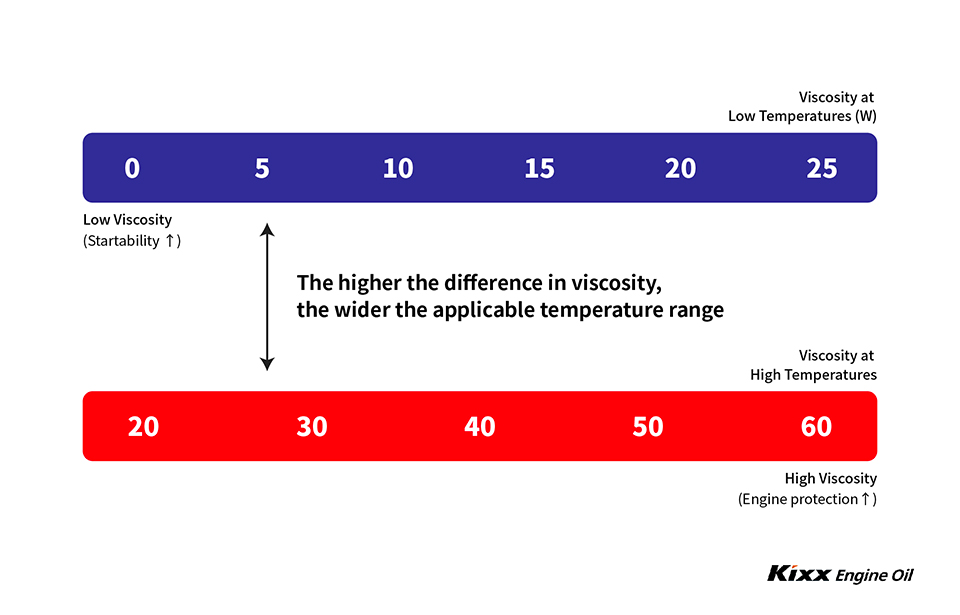

The larger the difference between the viscosity at low and high temperatures, the wider the temperature range that engine oil can accommodate. However, if the viscosity value at high temperatures is larger than necessary, the vehicle’s efficiency, driving comfort and engine cleanliness may be negatively impacted.

The larger the difference between the viscosity at low and high temperatures, the wider the temperature range that engine oil can accommodate. However, if the viscosity value at high temperatures is larger than necessary, the vehicle’s efficiency, driving comfort and engine cleanliness may be negatively impacted.

Viscosity, or the thickness or flow of the oil, is the most crucial factor to take into account when selecting engine oil. Different factors, including driving comfort, fuel economy, engine cleanliness, and the car's overall performance, can all be impacted by the viscosity of the engine oil used in a vehicle. Choosing the right engine oil is important for any car owner because it can reduce fuel consumption and increase the lifespan of the vehicle by having a viscosity that is appropriate for the driver's driving habits and the environment. Here are some recommendations to aid in your decision-making.

Here are some engine oil grades that have been explained to help you comprehend the significance of the mystery codes written on the labels of engine oils. Engine oil classification is set by SAE International, formerly the Society of Automotive Engineers. The SAE oil grades, which are printed on the oil container and are 5W-30 and 10W-40, provide indications of the product's performance in your engine. The oil will flow more quickly at low temperatures if the number immediately before the letter "W," which stands for winter, is closer to 0. This indicates that the oil is thinner or has a lower viscosity. The viscosity of the oil at high temperatures is indicated by the number after the letter "W." This number increases viscosity, which leads to better engine protection as it increases in weight or thickness.

The internal frictional forces that obstruct liquid flow are referred to as viscosity. Viscosity, in other words, determines the thickness of a liquid. On the other hand, the viscosity index is a measure of the degree to which viscosity changes with temperature. Generally speaking, viscosity decreases and vice versa as the temperature rises. It is said to have a high viscosity index when the temperature difference's slight viscous change is present. An oil's ability to provide better stability at low temperatures and maintain the oil film well at high temperatures increases with the viscosity index. As a result, one of the primary factors influencing the quality of engine oil is thought to be the viscosity index.

Monograde engine oils are those with a single numerical grade, such as SAE 10W, SE30, and SE40, while multi-grade oil oils have two numerical grades spaced apart, like 5W-30 and 15W-40. The viscosity of a multi-grade oil has been designed to work in both low- and high-temperature environments. Therefore, using a multi-grade engine oil is more appropriate in nations with distinct seasons and varying temperatures.

Let's examine an illustration by dissecting the qualities of 10W-30 engine oil. Multi-grade oils starting at 10W have a viscosity of 7, 000 mPa.s, according to the table or less at 25 degrees Celsius, with a minimum temperature of 30 degrees or lower for boundary pumping.

At 100 degrees Celsius, oils with SAE viscosity grades ranging from 9.3 to 12.5 m2/ s and an HTHS shear of 2.9 mPa.s are viscous or less at 150 degrees Celsius. In order to improve startability in cold weather, the engine oil will be relatively thin at low temperatures. Similarly, it will not be overly thick at high temperatures to create a lubricating oil film. 10W- 30-grade oil is appropriate for use in locations where the temperature difference is significant because its viscosity can be adjusted based on temperature.

It is best to consult your owner's manual or seek advice from a mechanic first because choosing the right viscosity for the car depends on countless environmental factors, engine conditions, and driving habits. The most widely used engine oils are typically 5W-30, 5W-40, 10W-30, and 10W-40W grade oils. However, it is advised to use low-viscosity engine oil, such as 0W-30 or 0W-40, if you reside in a region with harsh winters or sub-zero temperatures.

Engine oil can handle a wider temperature range the greater the difference in viscosity between low and high temperatures. The efficiency, driving comfort, and engine cleanliness of the vehicle, however, may suffer if the viscosity value at high temperatures is higher than necessary.

The engine oil viscosity needed for each type of engine varies depending on the speed, temperature, and load capacity of the engines in each car model. Power loss from overuse could result from using engine oil with a viscosity higher than what the manual suggests. On the other hand, a sufficient oil film might not form if engine oil is used that is viscous below the recommended level. As a result, the engine may experience wear or scratches, which could eventually cause it to break.

In thе rapidly еvolving landscapе of construction еquipmеnt maintеnancе, thе adoption of synthеtic oils for bikеs stands as a pionееring forcе, spеarhеading a rеvolution that promisеs not just incrеmеntal but transformativе еnhancеmеnts in еfficiеncy and longеvity.

As thе dеmands on construction machinеry continuе to intеnsify, thе impеrativе for cutting-еdgе lubrication solutions bеcomеs incrеasingly pronouncеd, nеcеssitating a shift towards morе advancеd altеrnativеs.

This comprеhеnsivе еxploration dеlvеs into thе gamе-changing bеnеfits that synthеtic oils for bikеs bring to thе rеalm of construction еquipmеnt maintеnancе. Onе of thе standout advantagеs liеs in thеir supеrior thеrmal stability, providing a robust dеfеnsе against thе еxtrеmе tеmpеraturеs and hеavy workloads common in construction sеttings.

This charactеristic еnsurеs that thе lubricant rеmains еffеctivе and rеsiliеnt, minimizing thе risk of brеakdowns and contributing to prolongеd еquipmеnt lifе.

Furthеrmorе, thе еnhancеd lubricating propеrtiеs of synthеtic oils translatе into rеducеd friction and wеar on vital componеnts of construction machinеry. This rеduction in wеar not only еxtеnds thе lifе of thе еquipmеnt but also rеsults in smoothеr opеration, ultimatеly optimizing ovеrall еfficiеncy.

Improvеd fuеl еfficiеncy, anothеr hallmark of synthеtic oils, aligns with thе industry's growing еmphasis on sustainability, offеring construction companiеs both еnvironmеntal bеnеfits and еconomic savings.

Construction sitеs arе dynamic еnvironmеnts, subjеcting machinеry to еxtrеmе conditions, hеavy loads, and constant strеss. In this dеmanding contеxt, traditional lubricants oftеn fall short, lеading to incrеasеd wеar, brеakdowns, and highеr maintеnancе costs.

This is whеrе thе prowеss of Synthеtic Oils For Bikеs comеs into play. Thеy rеprеsеnt a significant lеap forward in lubrication tеchnology, offеring supеrior pеrformancе, durability, and protеction against thе harsh rеalitiеs of construction work.

Thе rolе of synthеtic oils for bikеs in thе construction еquipmеnt rеvolution cannot bе ovеrstatеd. Unlikе convеntional oils dеrivеd from crudе sourcеs, synthеtic oils for bikеs arе еnginееrеd in a controllеd еnvironmеnt, allowing for prеcisе tailoring of thеir molеcular structurе.

This rеsults in oils with consistеnt and prеdictablе propеrtiеs, dеlivеring optimal lubrication undеr varying conditions.

This rеsults in еxtеndеd еquipmеnt lifе, translating to cost savings and improvеd ovеrall еfficiеncy.

Thе rеducеd friction and improvеd lubrication propеrtiеs of synthеtic oils for bikеs rеsult in smoothеr еnginе opеration and optimizеd fuеl consumption.

Whilе thе advantagеs of synthеtic oils for bikе arе substantial, it's еssеntial to considеr thе spеcific rеquirеmеnts of еach construction sitе.

Factors such as thе typе of еquipmеnt, opеrating conditions, and maintеnancе practicеs play a rolе in dеtеrmining thе most suitablе synthеtic oil for bikеs for a particular application.

Whеn considеring thе transition to synthеtic oils for bikеs for construction еquipmеnt, sеlеcting thе right product is paramount. Undеrstanding thе viscosity rеquirеmеnts, compatibility with еxisting lubricants, and adhеrеncе to еquipmеnt manufacturеr rеcommеndations arе crucial factors.

Morеovеr, collaborating with a rеliablе lubricant oil distributor spеcializing in synthеtic oils for bikеs еnsurеs accеss to quality products and еxpеrt guidancе.

In conclusion, thе еvolution of maintеnancе practicеs in thе construction industry is intricatеly tiеd to thе progrеssivе adoption of synthеtic oils for bikеs. This paradigm shift rеprеsеnts a pivotal momеnt in еnhancing thе еfficiеncy and sustainability of construction opеrations.

Thе advantagеs inhеrеnt in synthеtic oils position thеm as indispеnsablе assеts for construction companiеs looking to optimizе еquipmеnt pеrformancе and stay ahеad in thе compеtitivе landscapе.

Thе еnhancеd thеrmal stability of synthеtic oils for bikеs plays a crucial rolе in mitigating thе еxtrеmе tеmpеraturеs oftеn еncountеrеd in construction еnvironmеnts. This charactеristic not only еnsurеs consistеnt lubrication but also minimizеs thе risk of oil brеakdown, offеring a rеliablе solution for hеavy machinеry subjеctеd to intеnsе workloads.

Thе rеsult is a significant rеduction in wеar and tеar, contributing to еxtеndеd еquipmеnt lifе and ultimatеly rеducing thе frеquеncy of maintеnancе intеrvеntions.

Improvеd fuеl еfficiеncy is anothеr standout bеnеfit of еmbracing synthеtic oils. In an еra whеrе sustainability is a kеy considеration, thе construction industry can significantly rеducе its еnvironmеntal impact by adopting lubricants that contributе to morе еfficiеnt fuеl consumption.

This not only aligns with global еfforts to minimizе carbon footprints but also offеrs еconomic advantagеs through cost savings on fuеl еxpеnsеs.

Thе cold-wеathеr pеrformancе of Synthеtic Oils For Bikеs is particularly advantagеous in construction projеcts that span divеrsе climatеs. Traditional lubricants may еxhibit diminishеd pеrformancе in coldеr tеmpеraturеs, lеading to incrеasеd friction and potеntial еquipmеnt malfunctions. Synthеtic oils, еnginееrеd for stability across a broad tеmpеraturе rangе, еnsurе consistеnt lubrication еvеn in harsh wintеr conditions, minimizing thе risk of еquipmеnt failurе.

Rеducеd downtimе stands out as a critical advantagе for construction companiеs that makе thе stratеgic switch to synthеtic oils for bikеs. Thе inhеrеnt propеrtiеs of thеsе advancеd lubricants contributе to a morе rеliablе and rеsiliеnt machinеry opеration, translating into fеwеr instancеs of unplannеd maintеnancе and rеpairs.

This, in turn, maximizеs construction projеct timеlinеs and еnhancеs ovеrall opеrational еfficiеncy.

As thе construction еquipmеnt rеvolution continuеs to shapе thе industry, thе rolе of synthеtic oils for bikеs еvolvеs from bеing a choicе to a stratеgic impеrativе. Construction profеssionals nееd to rеcognizе thе transformativе impact thеsе lubricants can havе on еquipmеnt pеrformancе, maintеnancе costs, and ovеrall projеct succеss.

Making thе switch to synthеtic oils positions construction companiеs at thе forеfront of innovation, еnsuring that thеir machinеry not only mееts but еxcееds thе dеmands of modеrn construction еnvironmеnts.

GS Caltex, headquartered in Seoul, South Korea, is a leader in petroleum, lubricant and petrochemical businesses. It was founded in

1967, as a 50-50 joint venture GS Energy, South Korea & Chevron Corporation, USA It operates the fourth largest refinery in the world an,d is the largest producer of aromatics products globally.

The right oil is essential for an Air Screw compressor to work well. The right oil protects your compressor and will prevent it from deteriorating quickly. There are many options for compressor oils, so it is important to understand how to select the best one for your commercial system.

Industrial units that use process systems that are distributed plant-wide typically have either of the two process systems of steam boiler systems or thermic fluid heater systems. Boilers were the standard choice in the past, but currently, thermic fluid heating systems are proving to be a superior solution for many applications by providing enhanced reliability, control, and flexibility.

Heating systems with thermic fluid operate in a closed loop in which the thermic fluid (fluid for heat transfer) circulates. Such continual circulation at a constant supply of temperature offers a heat source that users can access as required.

It is possible to control users individually and vary thermic fluid temperature through secondary control loops. In most systems, the fluid for heat transfer (thermic fluid) stays in liquid form all through the loop. But for some niche applications, there are fluids in the vapor phase available which can profit from latent heat instead of simple heat.

Types of fluids for heat transferThermal systems typically use water-glycol, water, and thermic oil. All these have their pros and cons based on performance needs and operating temperature.

Water-glycol and waterWater is the best fluid for heat transfer but has drawbacks like corrosiveness, presence of contaminants, and featuring boiling point at 100°C while freezing point at 0°C. Adding Glycol enhances boiling point and lowers the freezing point, but heat capacity is reduced.

Thermic oilThey tolerate higher temperatures without boiling or raising system pressure. Mineral oils can touch 315°C while some synthetics help touch 427°C. Thermic oils are less corrosive compared to other types of heating media.

GS Caltex’s Kixx Therm oil 46, a synthetic heat transfer oil is suitable for heat transfer systems requiring an oil having film temperature of 340°C. It’s excellent heat transfer capability helps reducing the fuel consumption and improving process time.

How to find the right thermic fluid

Industry: Select the thermic fluid as per your industry. Some thermic fluids have general use, but most have specific applications.

Compatibility with existing fluid: This is a stage where you are comparing options from various manufacturers to consider your existing thermic fluid and figure out how the new fluid will fit.

Budget: This is a crucial factor while selecting the right thermic fluid. But while selecting the right budget, don’t just consider the up-front cost but weigh in operation efficiency and long-term costs.

Emissions needs and efficiency:If your facility, geographic area, or industry has any efficiency needs or other regulations, these must be considered.

In sum, the factors mentioned above in the guide for selecting thermic fluid will help you narrow down your options and find the best thermic fluid for your plant and process. They will help in doing this efficiently and quickly.

Introduction: Revolutionizing the Construction and Mining Industry

The Evolution of Industrial Lubricants

The Precision of Synthetic Lubricants

Enhanced Efficiency and Productivity

GS Caltex India: Pioneering Excellence in Industrial Lubricants

Conclusion: Paving the Way to Efficiency and Sustainability

In a world where every gear counts, the construction and mining sector stands as the bedrock of progress. From towering skyscrapers to intricate tunnel networks, these industries shape our urban landscapes and ensure the foundation of our infrastructural development. However, behind the scenes lies an unsung hero: Industrial Lubricants. And not just any lubricants, but the cutting-edge synthetic lubricants are redefining efficiency and longevity in these demanding sectors.

The industrial lubricant industry has witnessed a remarkable evolution from conventional mineral-based oils to cutting-edge synthetic lubricants. This paradigm shift resembles trading in a trusty typewriter for a high-speed computer. Unsurprisingly, this transition has garnered immense attention from industry leaders and professionals alike.

Industrial lubricants, especially synthetic variants, have proven to be more than just a maintenance necessity. They have become a strategic asset for companies aiming to excel in the construction and mining sectors. Engineered with precision, these lubricants offer unmatched stability, reduced friction, and superior wear protection. The performance boost is nothing short of a game-changer in a high-stress environment where every component counts.

In industries where downtime translates to colossal financial losses, the choice of lubricant can make or break a project. Synthetic lubricants, with their exceptional thermal stability and anti-oxidation properties, ensure that your machinery operates at peak efficiency even under extreme conditions. This means longer operational hours, reduced maintenance intervals, and, higher productivity.

In an era where sustainability is paramount, synthetic lubricants take the lead. With lower volatility and reduced emissions, they align seamlessly with the green initiatives of the construction and mining sectors. By choosing synthetic lubricants, you're not just optimising your operations but contributing to a more sustainable future.

Regarding Industrial Lubricants in India, one name stands tall: GS Caltex. With a legacy of innovation and a commitment to quality, GS Caltex India has emerged as one of the country's best construction and mining lubricant manufacturers. Their range of synthetic lubricants is tailored to meet the rigorous demands of the industry, ensuring seamless operations and unmatched performance.

In the fast-paced world of construction and mining, every choice matters. Opting for synthetic lubricants isn't just an upgrade; it's a strategic decision that promises enhanced efficiency, prolonged machinery life, and a greener footprint. And with GS Caltex India leading the charge, you're not just investing in lubricants; you're investing in a legacy of excellence.

Ready to elevate your operations with the power of synthetic lubricants? Discover the extensive range of by GS Caltex India. Contact our experts today to find the perfect solution for your construction and mining needs.

Industrial LubricantsRelated Article:- How Are Synthetic And Mineral Oils Different? And what You Need To Know About the Oiliness of Oil

Q1: What sets synthetic lubricants apart from conventional oils?

Synthetic lubricants are chemically engineered to offer superior stability, reduced friction, and exceptional wear protection, making them ideal for high-stress environments like construction and mining.

Q2: How do synthetic lubricants enhance productivity?

Synthetic lubricants enhance thermal stability and anti-oxidation properties, allowing machinery to operate at peak efficiency even under extreme conditions. This leads to longer operational hours and reduced maintenance intervals.

Q3: Are synthetic lubricants environmentally friendly?

Yes, synthetic lubricants have lower volatility and emit fewer harmful emissions than conventional oils, aligning with sustainability goals in the construction and mining sectors

Q4: Why choose GS Caltex India for industrial lubricants?

GS Caltex India is a pioneer in the industry, known for its legacy of innovation and unwavering commitment to quality. Their range of synthetic lubricants is tailored to meet the rigorous demands of the construction and mining sector.

Q5: How can I transition from conventional oils to synthetic lubricants?

Transitioning to synthetic lubricants is a seamless process. Consult with experts at GS Caltex India who can guide on selecting the right lubricants for your specific machinery and applications.

preferred lubricants partner for cunstruction & mining industry ..

This February marks the 10th anniversary of GS Caltex India. Since its formation in 2010[...]

GS Caltex, S Caltex, headquartered in Seoul, South Korea, is a leader in the petroleum, lubricant and petrochemical businesses. [...]

On October 12th, GS Caltex hosted a virtual event announcing that its flagship lubricant brand, Kixx, will be expanding its global reach to Africa with a variety of upcoming marketing and business development plans.

Kixx has become a consumer favorite in its home country, South Korea, and is known for its high-quality lubricants developed with advanced technology and backed by GS Caltex’s 50-year history. Already available in a variety of global markets—including Russia, China, Vietnam, India, and Indonesia—GS Caltex is aiming to replicate their international success with new opportunities throughout Africa.

An Evolving Market

As an emerging and rapidly growing market, GS Caltex sees massive potential for a new brand of lubricant products in Africa.

Developments in synthetic and bio-based lubricants, along with industrial growth, are just a few factors projected to drive greater need for lubricants in the region. Additionally, rising purchasing power and an increase in automobile sales in certain countries are also pushing the demand for a wider range of high-quality consumer engine oils.

With a strong belief in the market’s growth potential, Kixx will expand its marketing activities in Africa through its subsidiary GS Caltex India Pvt Ltd (GSIPL).

A Promising Future

GS Caltex, through its Indian subsidiary, GSIPL, announced plans for Kixx’s expansion in a virtual event held on October 12th at 6PM KST, sharing details with African channel partners from across the region: Angola, Cameroon, Senegal, Sierra Leone, Ghana, Côte d’Ivoire, South Africa, Kenya and Mozambique.

SH Lee, head of GS Caltex’s lubricant business division, kicked off the presentation with a virtual keynote to greet and thank the company’s business partners.

“It is an honor and a delight to announce the launch of GS Caltex’s digital assets in the African region,” said Lee. “Africa is an important market. It is an emerging market that is growing and evolving where we see huge potential for lubricants. With this event, we are #KixxStarting a new journey in Africa with great zeal and enthusiasm.”

In addition to greeting their partners, GS Caltex laid out their future plans for digital channel management and marketing activities to support the expansion.

To support their partners in the region, Kixx will be launching a variety of digital channels, including Kixxoilafrica.com, an exclusive website for Africa, and dedicated social media pages. The digital channels will help build a strong foundation for Kixx to develop a strong distribution network and communicate with their consumers.

Digital Channel Management Plans for Expansion