Table of content

Mining equipment is an essential part of the mining industry, enabling the extraction of valuable resources from the earth. These machines often operate in harsh and demanding conditions, subject to heavy loads, extreme temperatures, and dust exposure. To ensure the smooth functioning and longevity of mining equipment, the proper use of lubricants is of paramount importance. In this blog post, we will explore the critical role and importance of lubricants in the mining equipment, emphasizing their significance in enhancing performance and reducing downtime. We'll also highlight the use of heavy-duty lubricants provided by GS Caltex India, a leading name in the industry.

Proper Usage of Fuel

Mining equipment relies heavily on fuel to power its operations. However, using fuel alone is insufficient to ensure optimal performance and efficiency. Lubricants play a vital role in this context by reducing friction and wear between moving components. By applying the right lubricants, such as heavy-duty mining lubricants, operators can achieve reduced fuel consumption, lower emissions, and increased power output. The use of high-quality lubricants also protects the engine from premature wear, enabling it to operate efficiently for an extended period.

GS Caltex India offers a range of advanced lubricants specifically designed for the mining industry. These products not only enhance the equipment's performance but also contribute to overall cost savings and environmental sustainability through improved fuel economy.

Frequent Maintenance Not Required

Frequently situated in remote regions, mining operations face difficulties and high expenses in carrying out regular maintenance and repairs. To address this, heavy-duty lubricants assume a vital role by minimizing the necessity for

By choosing the right lubricants, mining companies can significantly extend the equipment's service intervals, leading to increased productivity and minimized downtime. GS Caltex India's heavy-duty lubricants are engineered to withstand the harshest conditions, ensuring mining equipment operates reliably and efficiently with reduced maintenance requirements.

Different Viscosity Levels

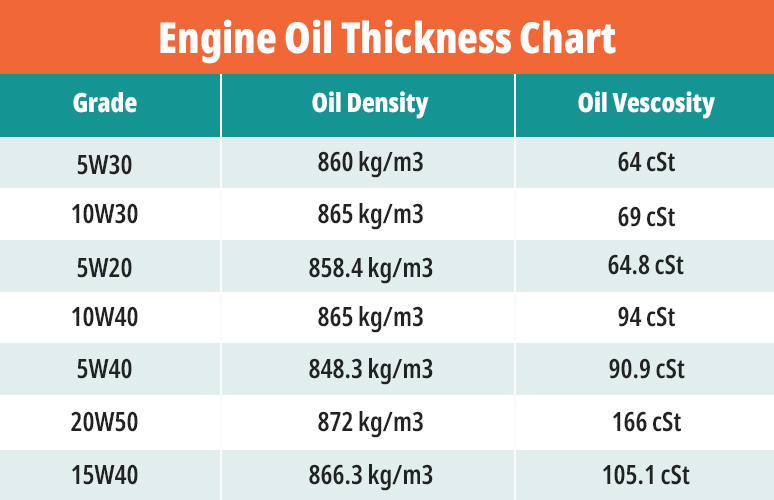

Mining equipment operates under diverse temperature conditions, ranging from scorching heat to freezing cold environments. Lubricants with varying viscosity levels are crucial to maintaining optimal performance throughout these extreme conditions.

High viscosity lubricants are suitable for heavy load-bearing components, providing robust film strength to prevent metal-to-metal contact and reduce wear. On the other hand, low-viscosity lubricants are ideal for cold climates, as they ensure smooth startup and fluidity even at lower temperatures.

GS Caltex India offers a comprehensive range of lubricants with different viscosity levels, tailored to suit various mining equipment requirements. Whether it's high temperatures or freezing conditions, their lubricants guarantee consistent performance and protection.

Friction

Friction is a significant challenge faced by mining equipment, leading to loss in power and so energy, increased fuel consumption, and accelerated wear of components. By utilizing advanced lubricants, friction can be significantly reduced, enhancing overall efficiency and minimizing energy losses.

GS Caltex India's heavy-duty lubricants are formulated with cutting-edge additives to provide excellent anti-friction and anti-wear properties. By mitigating friction-related issues, these lubricants ensure smoother operation, reduced maintenance costs, and increased equipment lifespan.

Oxidation and Aeration

In mining operations, some equipment may be exposed to high temperatures and harsh environmental conditions, leading to oxidation and aeration of lubricants. Oxidation can result in oil thickening and the formation of harmful sludge, while aeration can decreased lubricant effectiveness and leads to cavitation, micro-pitting, pitting, and spalling.

GS Caltex India's heavy-duty lubricants are engineered to resist oxidation and aeration, ensuring prolonged oil life and consistent performance even in challenging environments. By maintaining the integrity of the lubricants, mining companies can avoid costly equipment failures and extend oil drain intervals.

Conclusion

In conclusion, lubricants play a crucial role in mining equipment, enabling smooth operations, reducing friction, and protecting vital components. GS Caltex India offers a range of high-quality heavy-duty lubricants designed explicitly for the mining industry's demanding conditions. By utilizing these advanced lubricants, mining companies can enhance equipment performance, increase productivity, and minimize downtime. Additionally, the proper use of lubricants can contribute to cost savings, improved fuel economy, and reduced environmental impact.

Investing in quality lubricants from GS Caltex India is not only a smart business decision but also a commitment to sustainable mining practices and equipment longevity. Embracing the right lubrication solutions is the key to unlocking the full potential of mining equipment and maximizing the productivity of mining operations.

Frequently Asked Question's

Q1: Why are lubricants essential for mining equipment?

Mining equipment relies heavily on lubricants to minimize friction between moving parts, thereby preventing wear and tear and ensuring seamless operations. Additionally, these lubricants safeguard critical engine components, promote fuel efficiency, and prolong the equipment's lifespan, resulting in lower maintenance expenses and enhanced productivity.

Q2: How do heavy-duty lubricants help in mining operations?

Heavy-duty lubricants, such as those provided by GS Caltex India, are specifically designed to withstand the harsh conditions encountered in mining operations. These lubricants offer superior wear protection, reduce the need for frequent maintenance, and ensure consistent performance even in extreme temperatures and challenging environments.

Q3: Can lubricants contribute to fuel economy in mining equipment?

Yes, the use of high-quality lubricants can significantly contribute to fuel economy in mining equipment. By reducing friction and wear, lubricants optimize engine performance, leading to reduced fuel consumption and lower emissions. This not only helps mining companies save on fuel costs but also promotes environmental sustainability.

Q4: How do viscosity levels in lubricants impact mining equipment performance?

Viscosity levels in lubricants play a vital role in ensuring optimal performance in different operating conditions. High viscosity lubricants provide robust film strength for heavy load-bearing components, while low viscosity lubricants ensure smooth startup and fluidity in colder climates. Choosing the right viscosity level is essential for maintaining efficiency and extending the equipment's lifespan.

Q5: Can using lubricants reduce downtime in mining operations?

Yes, using the right lubricants, especially heavy-duty ones, can reduce downtime in mining operations. These specialized lubricants protect critical components, extending their life and reducing the risk of unexpected breakdowns. Consequently, the equipment experiences fewer failures, leading to increased productivity and minimized downtime.

Q6: How do GS Caltex India's heavy-duty lubricants address oxidation and aeration challenges?

GS Caltex India's heavy-duty lubricants are formulated with advanced additives to resist oxidation and aeration. This ensures prolonged oil life and consistent lubricant performance even in high-temperature and harsh environments. By preventing oil thickening and harmful sludge formation, these lubricants help maintain equipment reliability and extend oil drain intervals. Controlling foam avoiding cavitation, micro-pitting, pitting, and spalling and help to increase the equipment durability.

Q7: Can lubricants improve the overall efficiency of mining equipment?

Absolutely! Lubricants play a pivotal role in improving the overall efficiency of mining equipment. By reducing friction and energy wastage, lubricants contribute to smoother operations and lower fuel consumption. Additionally, lubricants protect components from wear, reducing maintenance requirements and optimizing the equipment's overall performance.

Q8: Are GS Caltex India's lubricants suitable for all types of mining equipment?

GS Caltex India offers a comprehensive range of lubricants designed explicitly for the mining industry. Their product portfolio includes lubricants suitable for various mining equipment types, ranging from heavy machinery to specialized vehicles. Whether it's dump trucks, excavators, or loaders, GS Caltex India's lubricants cater to the diverse needs of mining operations.

Q9: How do lubricants contribute to sustainable mining practices?

Lubricants contribute to sustainable mining practices in multiple ways. By reducing fuel consumption and emissions, they promote environmental responsibility. Moreover, lubricants' ability to extend equipment lifespan and reduce maintenance needs leads to lower resource consumption and waste generation, supporting the principles of sustainable mining.

Q10: Are there any specific safety considerations while using lubricants in mining equipment?

Lubricants contribute to sustainable Despite the performance and longevity benefits that lubricants bring to mining equipment, safety remains of utmost importance. Adhering to manufacturer guidelines and recommendations regarding lubricant usage, storage, and disposal is imperative. Regular inspections and maintenance play a critical role in preserving the equipment's optimal functionality and ensuring its safe operation within the mining environment. mining practices in multiple ways. By reducing fuel consumption and emissions, they promote environmental responsibility. Moreover, lubricants' ability to extend equipment lifespan and reduce maintenance needs leads to lower resource consumption and waste generation, supporting the principles of sustainable mining.